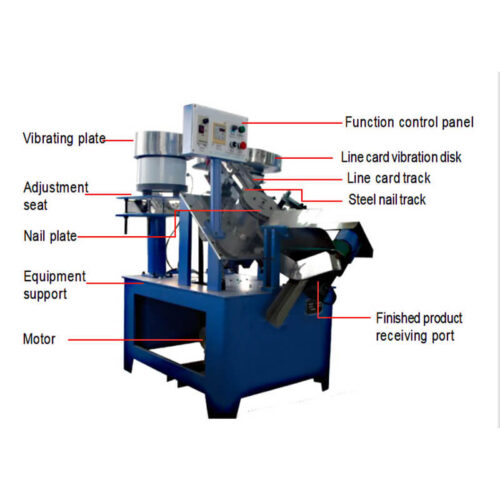

Heat Sink Riveting Machine

Main Features

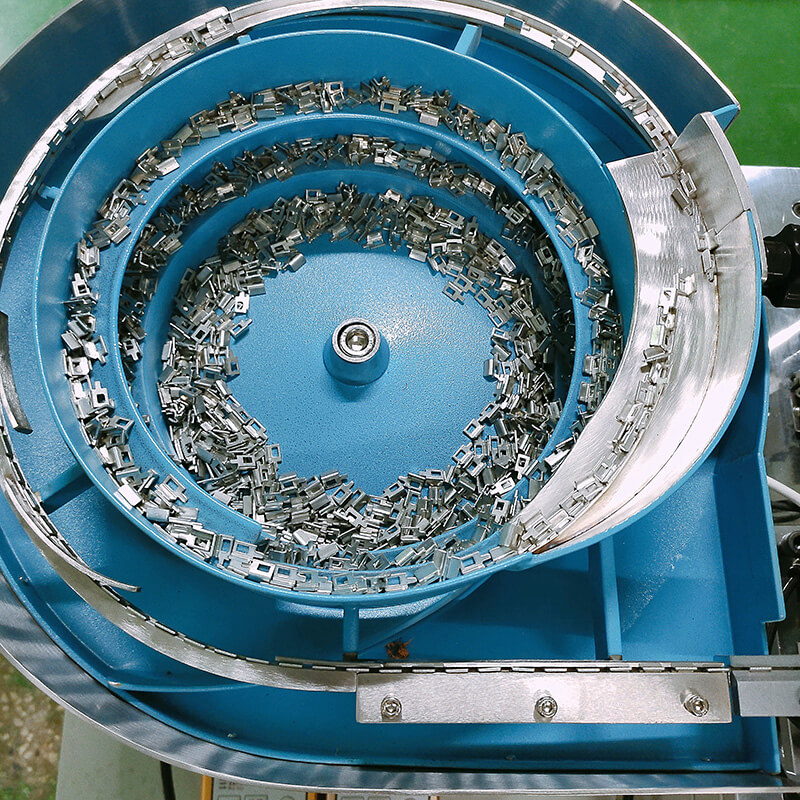

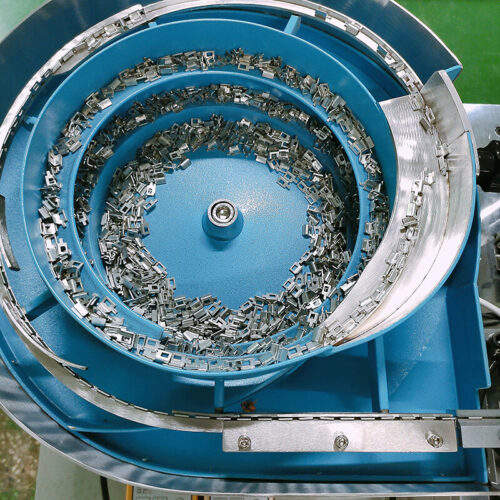

The Heat Sink Riveting Machine is a customized machine. This machine uses a vibrating plate to transport the heat sink and accessories that need to be riveted to the central processing turntable for riveting. This machine is simple and fast and solves the problems of slow manual operation and unstable quality. Greatly improve the quality of products and finished products.

Technical Parameters

| Device | Heat Sink Riveting Machine |

| Model | Zpj-Jr-20 |

| Power | 220V |

| Function | Riveting |

| Capacity | 60Pcs Per Minute |

| Hose Range | Max 2M Length Or Customized |

| Scope Of Application | Electronic Parts Or Metal Terminal Plate |

| Air | 4Kg-6Kg |

Heat Sink Riveting Machine Main Functions

- Radiator riveting: The radiator riveting machine can automatically connect the radiator fins and heat pipes together through the riveting process, so as to ensure the firm structure and heat dissipation effect of the radiator.

- Radiator forming: The radiator riveting machine can connect the radiator fins and radiator tubes in a specific arrangement to form a complete radiator according to the required specifications and requirements of the radiator.

- Improve production efficiency: The radiator riveting machine can realize automatic production, improve production efficiency and production capacity, and reduce labor costs and production cycles.

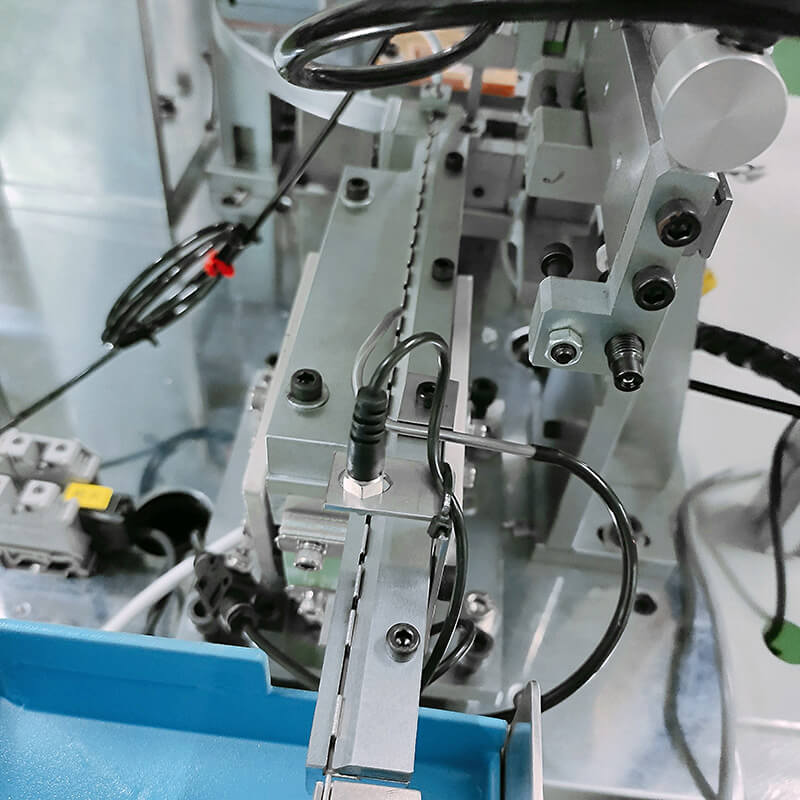

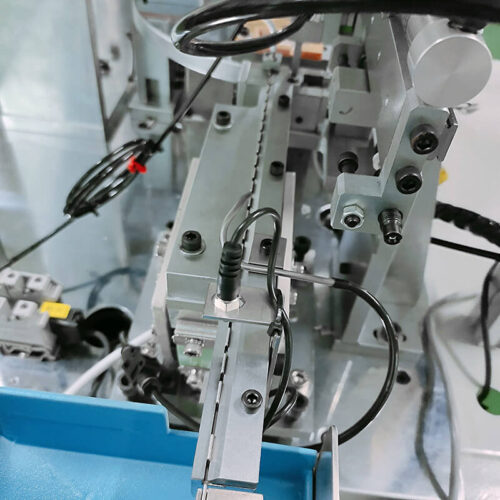

- Precision control: The radiator riveting machine adopts a precision control system, which can control the riveting strength, riveting time, riveting position, and other parameters of the riveting process to ensure the manufacturing accuracy and quality of the radiator.

- Safety guarantee: The radiator riveting machine has safety protection measures, such as fault self-diagnosis, emergency shutdown, and other functions, which guarantee the safety and stability of the production process.

If you want to contact me, please email us.

Heat Sink Riveting Machine Production Line

- Plate cutting workstation: used to cut aluminum or copper sheets into suitable-size plates.

- Drilling station: used to drill holes in the plate.

- Heat pipe processing workstation: used for processing heat pipes.

- Riveting station: riveting the plates and heat pipes together.

- Painting workstation: used for painting the radiator.

- Assembly Workstation: Assembling the individual parts of the radiator together.

- Inspection Workstation: Carry out a quality inspection on radiators.

Reviews

There are no reviews yet.