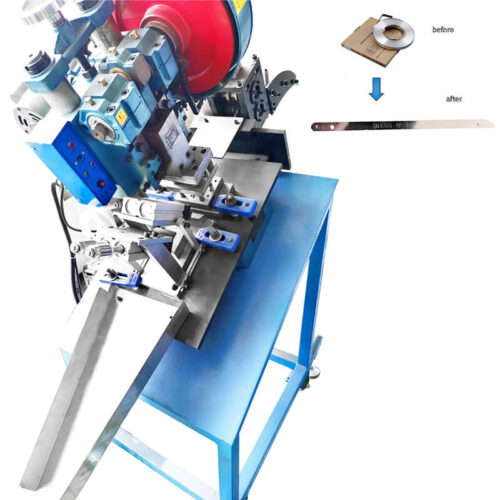

Semi-Automated Assembly Machine

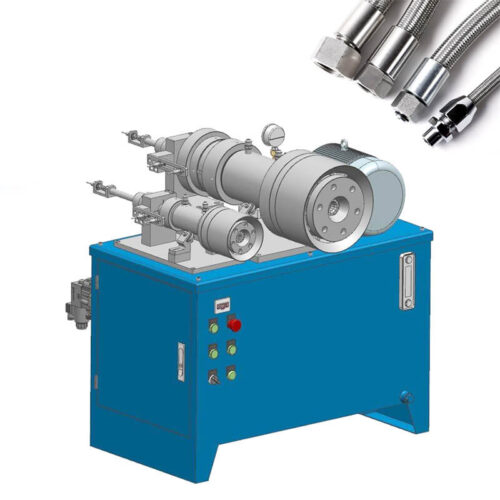

As an automated assembly machine manufacturer, we have rich experience and expertise and are committed to designing and manufacturing various types of assembly line machines, like an automated assembly machine, a semi-automated assembly machine, a multi-station assembly machine, a high-speed assembly machine, and a custom assembly machine.

Our attention to detail and quality ensures that custom assembly equipment is a perfect match for the customer’s production line.

If you are looking for a reliable automated assembly line manufacturer, you can work with us.

Automated assembly machine and semi-automatic assembly machine are two different assembly equipment.

Automated assembly machine is a fully automated assembly equipment that can independently complete the entire assembly process, from parts supply to final product assembly, reducing the need for manual operations.

Automated assembly machines usually have highly automated functions, including automatic feeding, automatic positioning, automatic assembly, and automatic quality inspection.

The advantages of an automatied assembly machine are high speed, high efficiency, and accuracy, and are suitable for mass production and demanding assembly tasks.

A semi-automatic assembly machine is a partially automated assembly equipment that requires human intervention and operation to complete some key assembly steps.

Semi-automated assembly machines usually have some automated functions, but require operator participation in some links.

Semi-automatic assembly machines are suitable for small and medium batch production and some customized assembly tasks.

In general, the main difference between automated assembly machines and semi-automatic assembly machines lies in the degree of automation and the mode of operation.

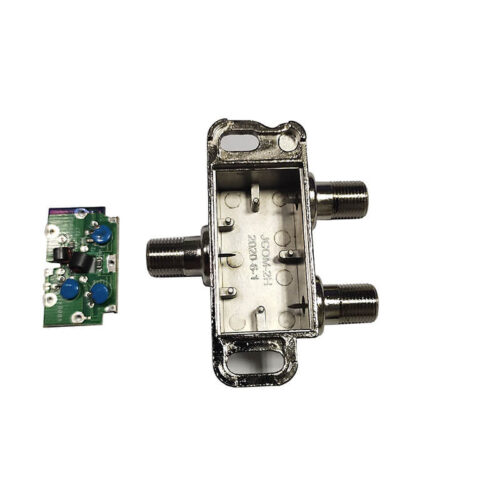

Efficiency: An automatic assembly machine can perform assembly tasks in a high-speed and stable manner, greatly improving production efficiency.

Accuracy: An automatic assembly machine uses advanced sensors and control systems to enable highly precise assembly operations.

Consistency: An automatic assembly machine can maintain highly consistent assembly quality, whether over long runs or across multiple assembly cycles.

Production scalability: An automatic assembly machine can easily meet the needs of mass production, and can also flexibly adapt to small batch production and customized production.

Safety: An automatic assembly machine handles potentially hazardous parts, reducing operator exposure to potentially hazardous substances or environments.