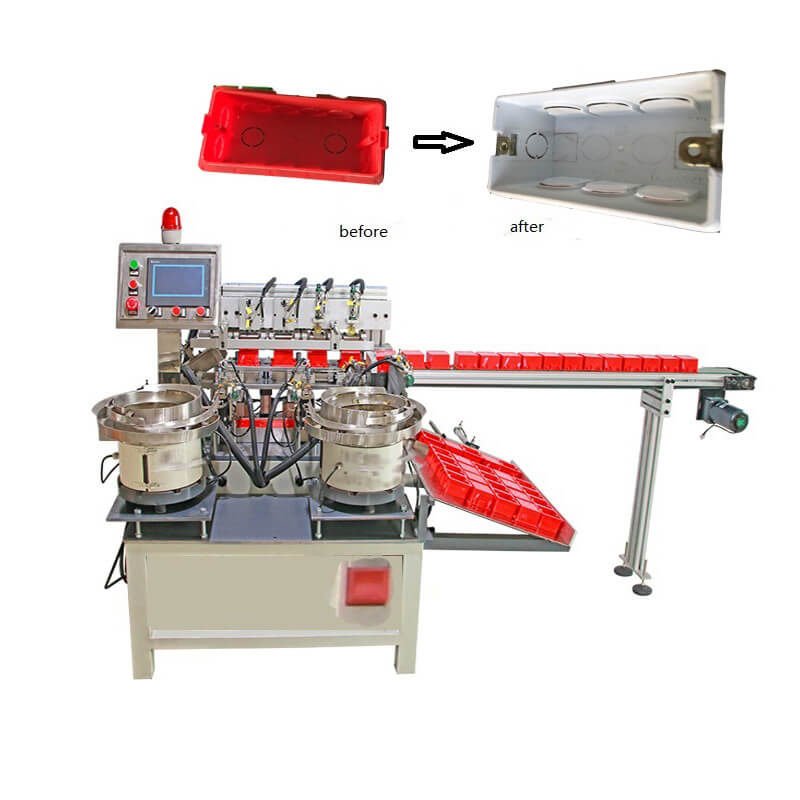

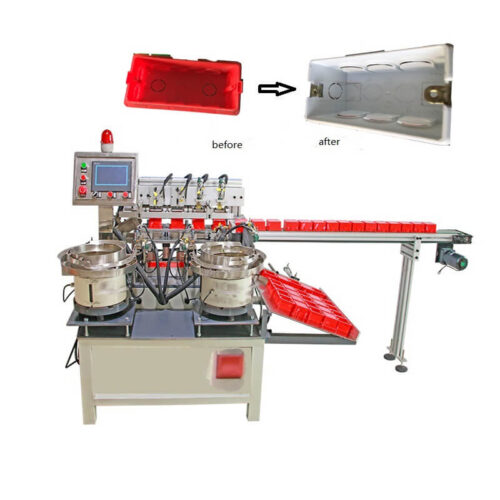

Junction Box Making Machine

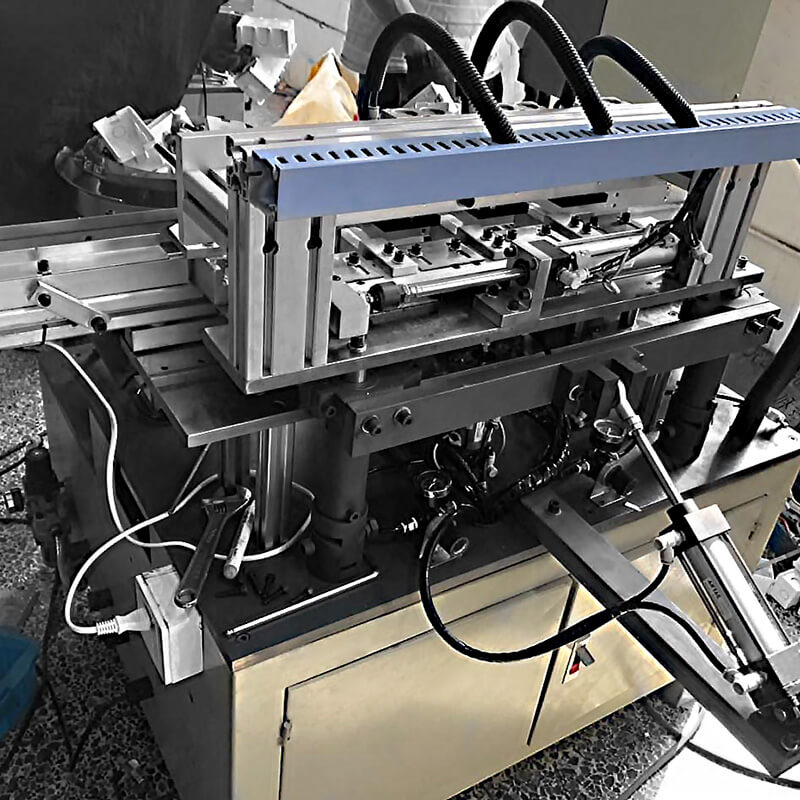

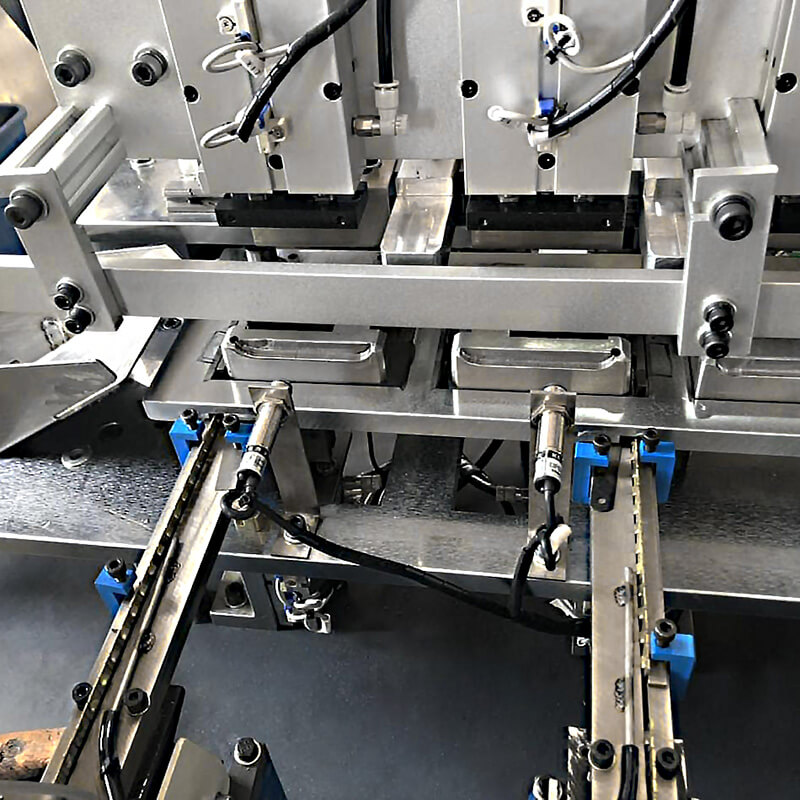

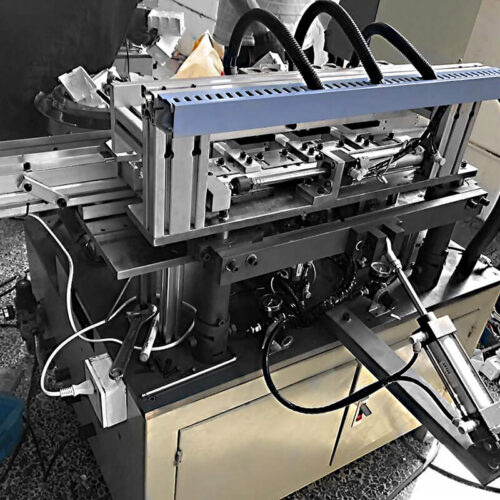

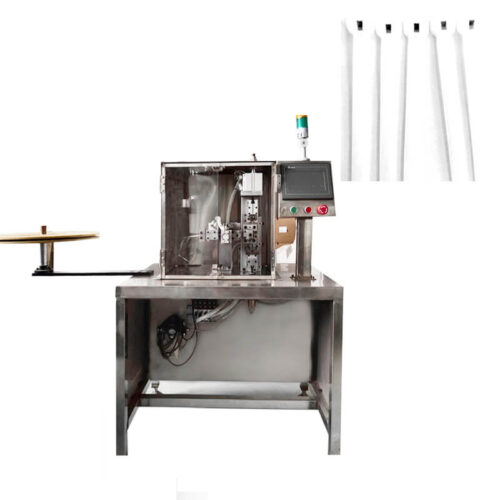

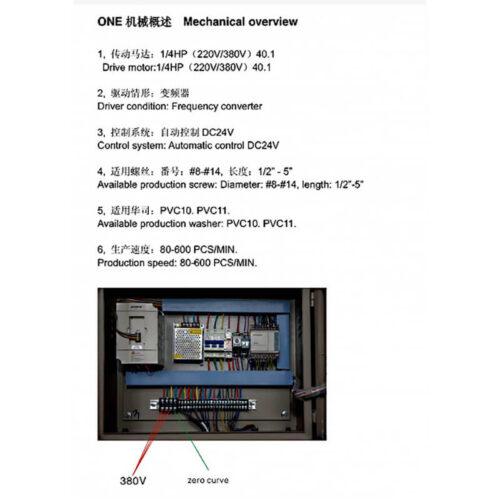

The electrical junction box making machine adopts advanced PLC and screen display and uses Taiwanese sensors and cylinders to ensure good quality and prolong service life.

One worker can look after 2 machines.

Can replace 6 employees.

The standardization of products is also more assured.

Featured Video

Conclusion

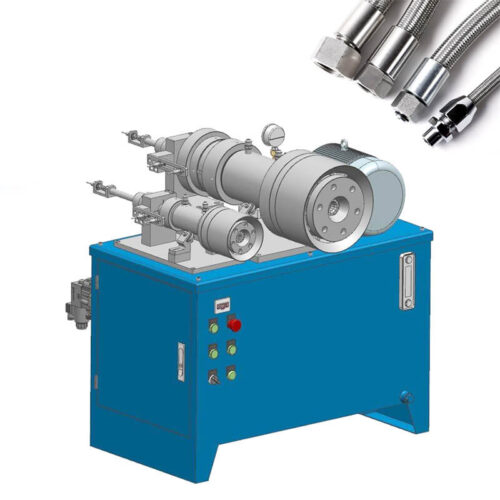

We have worked on several projects and if you wish you can send us your ideas.

So our team can be ready to discuss functional specifications.

We will customize the most suitable plan for you according to your needs.

If you would like to inquire about information, please get in touch with us by email.

About Junction Box Making Machine

Efficient production: It can automate continuous production and improve production efficiency.

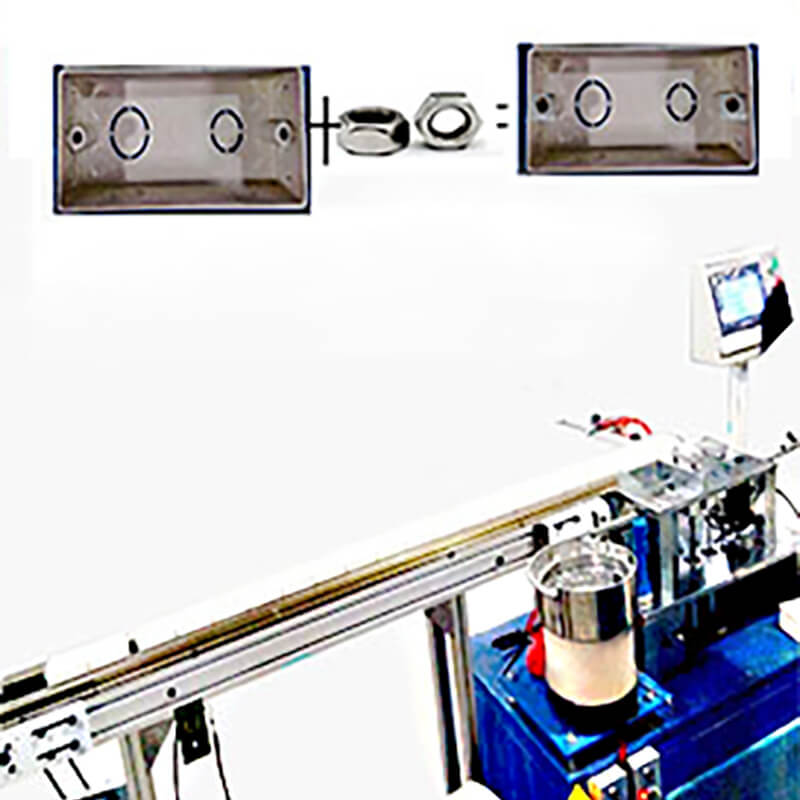

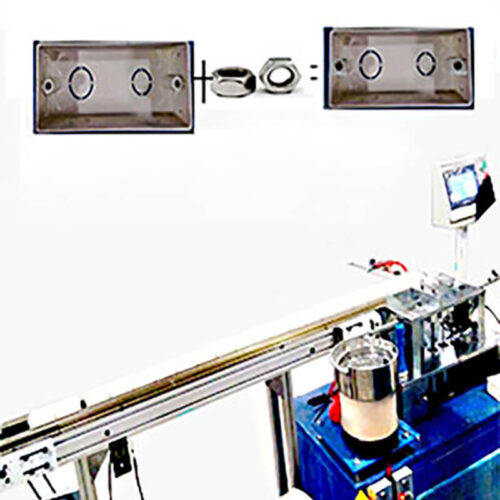

Precise Forming: It can make high-precision wire box molds to ensure product quality and consistency.

Diversified production: The mold can be replaced according to demand to adapt to the production of wire box molds of different shapes and sizes.

The working principle of the plastic junction box making machine is basically heating and injecting plastic granules or granulated molten materials into the mold, then cooling and forming, and finally getting the required wire box mold.

Electrical junction box making machine is widely used in the wire box production industry.

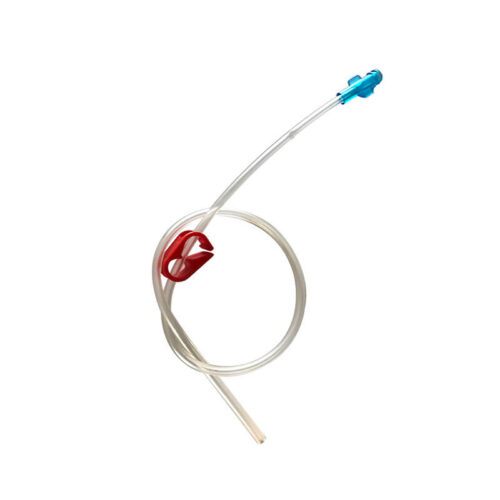

Wire boxes are devices used to install and protect wire connections, and are commonly used in construction, electricity, communications, and other fields.

Reviews

There are no reviews yet.