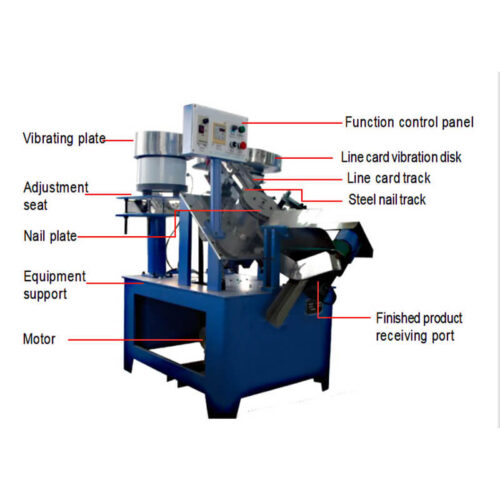

Plastic Cap Assembly Machine

Main Features

Plastic Cap Assembly Machine is a 3-piece assembly machine and testing machine. You need to insert the plastic part and the paper gasket into the lid and check the tightness of the top at the same time. This machine can be suitable for producing cosmetics, daily necessities, and other kinds of covers, and can be customized to the required size and function. The use of high-quality sensors, air cylinders, display screens, and PLC ensures excellent performance and long-term use experience, simple and easy to operate, one worker can manage at least 3 machines.

Technical Parameters

| Speed | 30Pcs Per Minute |

| Measurement | 1.2×0.8×1.6M |

| Delivery Time | 65Days |

| Guarantee | 1Year |

| Power | 220V |

| Certificate | Ce |

| Package | Wooden Box |

| Hs Code | 8479899990 |

Plastic Cap Assembly Machine Main functions

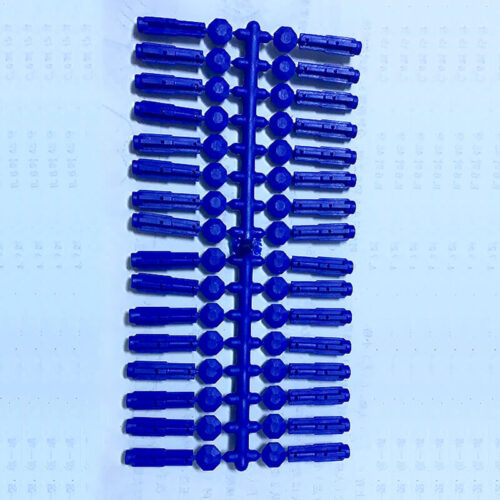

- Separation: Separate the various parts of the cover for subsequent processing and assembly.

- Feeding: Sending individual parts into the assembly line for the next assembly operation.

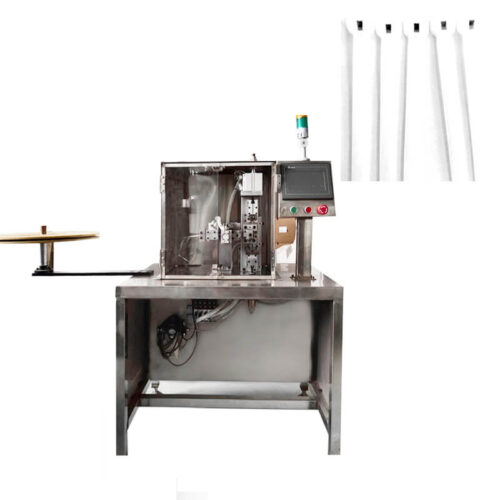

- Assembly: Assemble the various parts of the cover into a complete cover product according to a certain process. This process may involve many different operations such as assembly, welding, pressing, etc.

- Inspection: Inspect the assembled lid products to ensure the quality of the products meets the requirements.

- Packing: Pack cap products that meet the requirements for transportation and storage.

Plastic Cap Assembly Machine Production Line

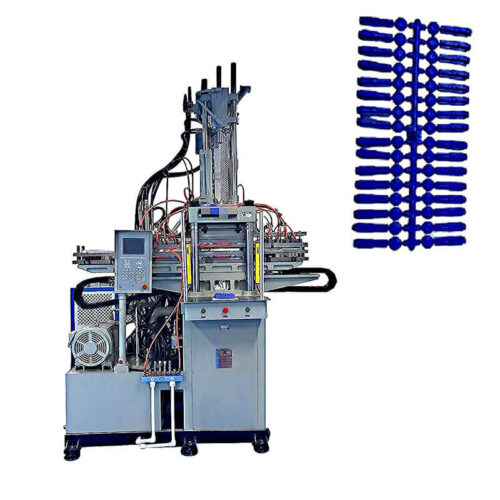

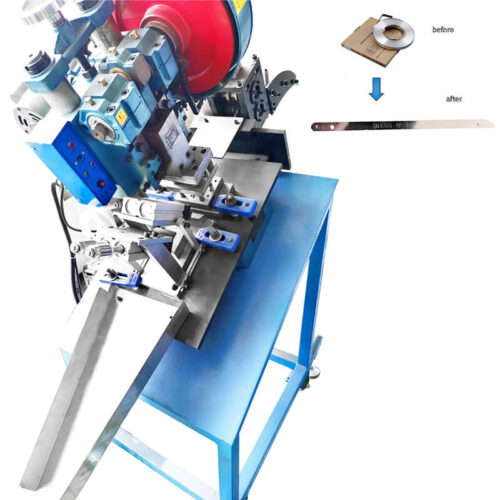

- Plastic Injection Molding Machine: Used to inject molten plastic into the mold to make the cover’s shell.

- Cap Assembly Machine: Used to assemble the shell and liner together to form a complete cap.

- Automatic feeding system: used to convey plastic pellets into the injection molding machine and transfer the assembled cap to the next workstation.

- Quality inspection system: used to check whether the size, shape, color, and other quality indicators of the cover meet the requirements.

- Packaging system: used to pack the assembled lids into boxes or bags for shipping and sale.

- These components can be adjusted and configured according to specific production needs and scale. For example, more injection molding machines and assembly machines can be added to increase production capacity, or more quality inspection systems can be added to improve product quality.

Reviews

There are no reviews yet.