Thermal Circuit Breaker Assembly Machine

Main Features

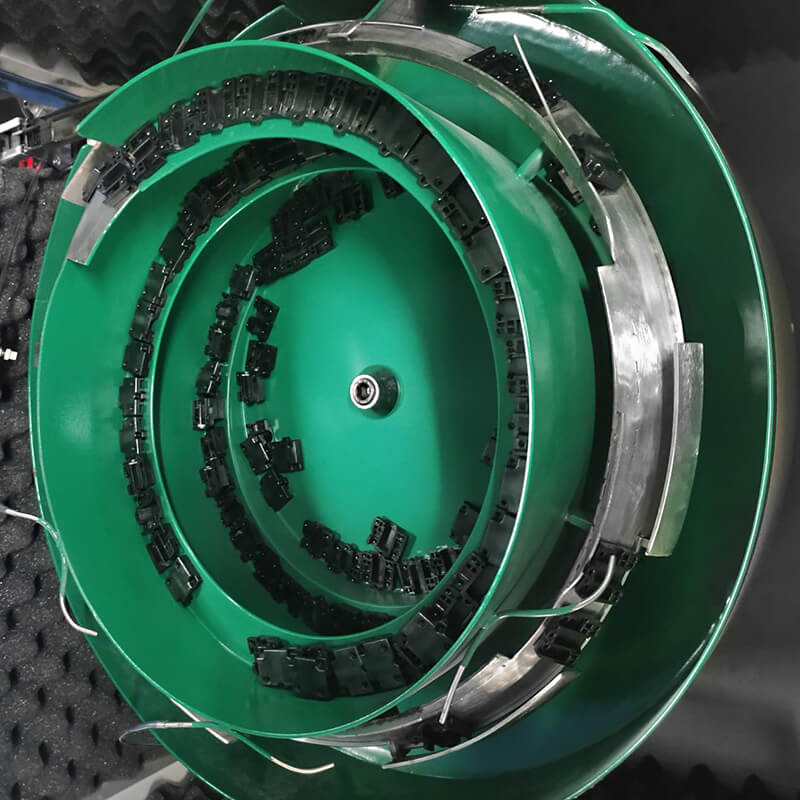

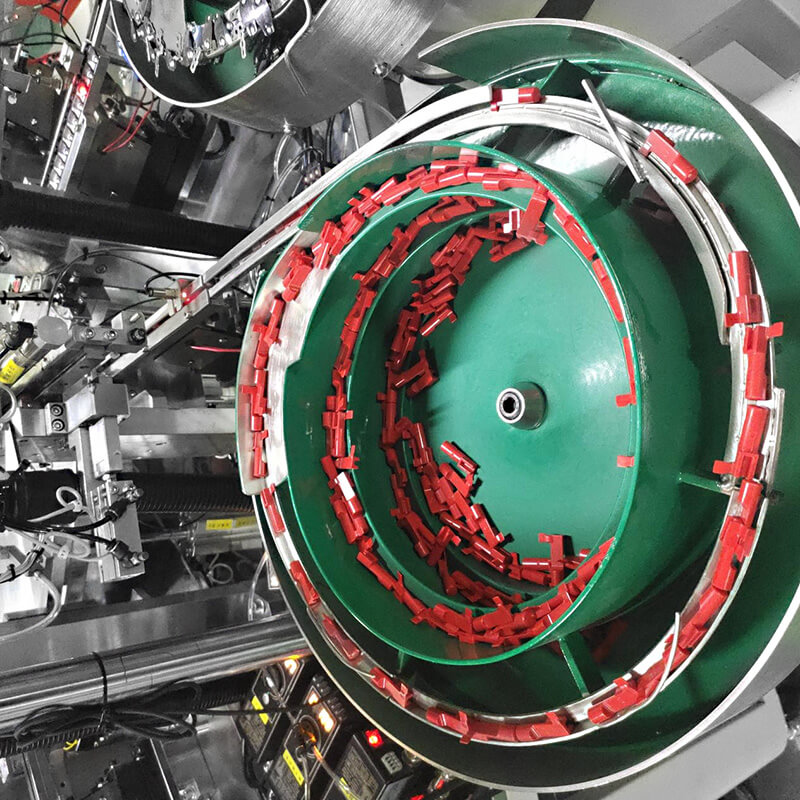

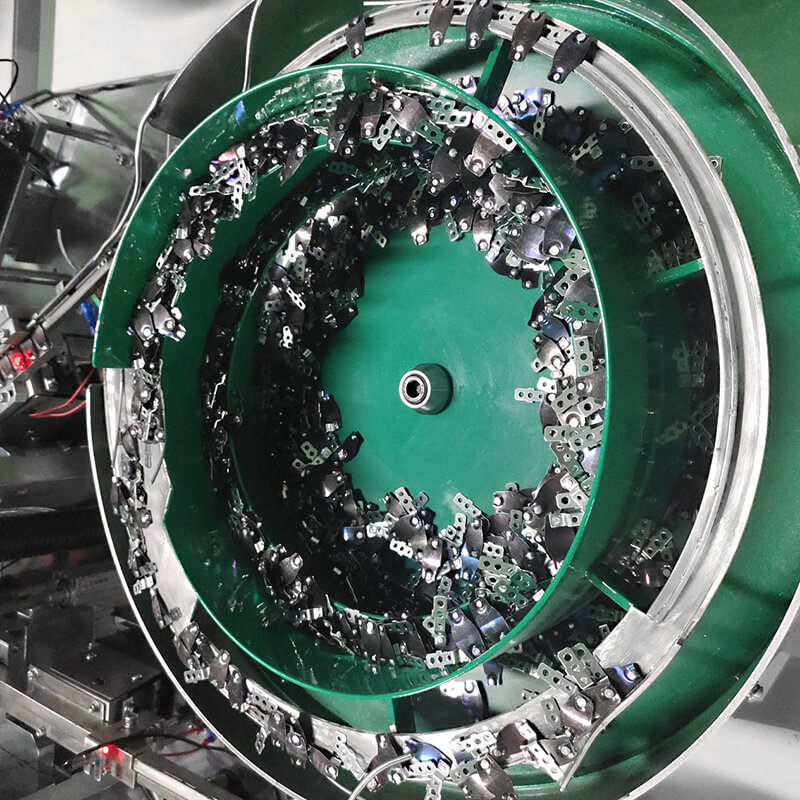

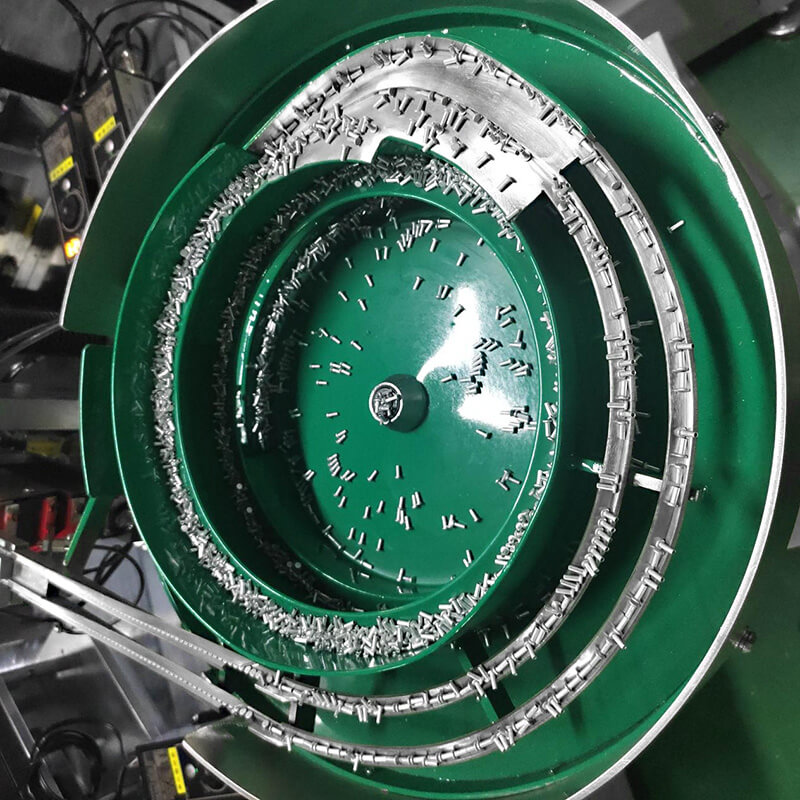

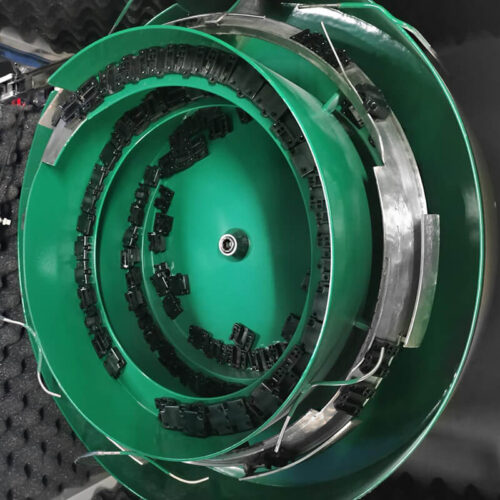

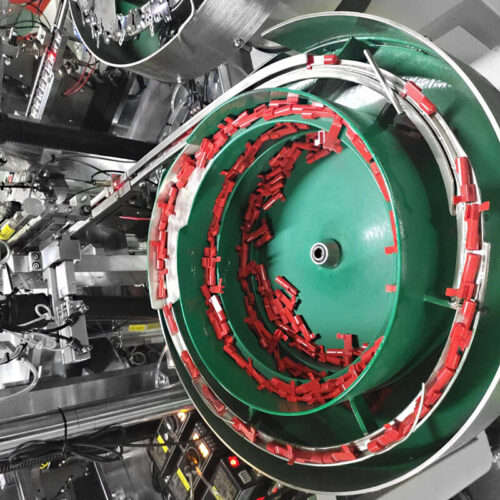

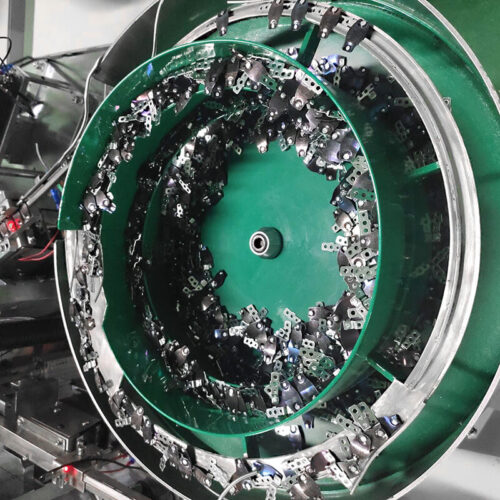

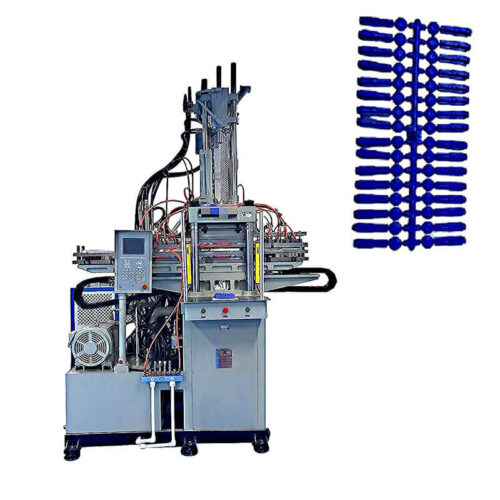

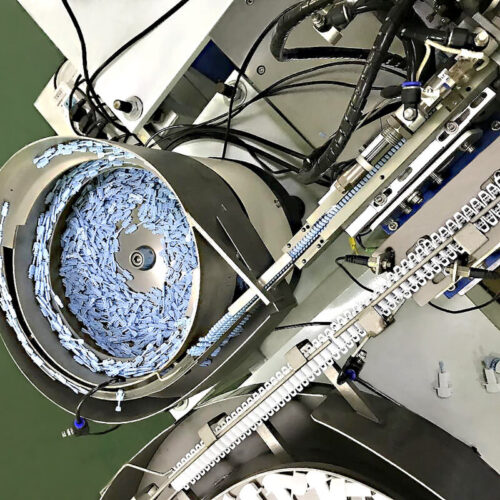

The temperature control switch of the Thermal Circuit Breaker Assembly Machine is assembled from 12 parts. Therefore, we need to use 7 vibrating plates to transfer the heads to the central processing station as required and assemble them in sequence according to the steps. This machine can save at least 4 manpower. Significantly reduces the time and labor required for product assembly. It is fast and efficient, and the product damage rate is also significantly reduced.

Technical Parameters

| Speed | 20Pcs Per Minute |

| Measurement | 1.2×1.2×1.2M |

| Delivery Time | 65Days |

| Guarantee | 1Year |

| Power | 220V |

| Certificate | Ce |

| Package | Wooden Box |

| Hs Code | 8479899990 |

| Driven Type | Electronics |

| Machine Name | Thermal Circuit Breaker Assembly Machine |

Thermal Circuit Breaker Assembly Machine Main functions

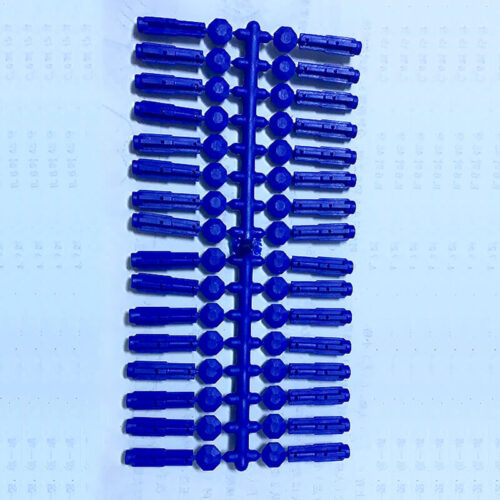

- Assembling the arc chamber: The arc chamber in the thermal circuit breaker is an important part responsible for carrying and isolating the arc. The assembly machine can assemble the arc chamber and other parts together.

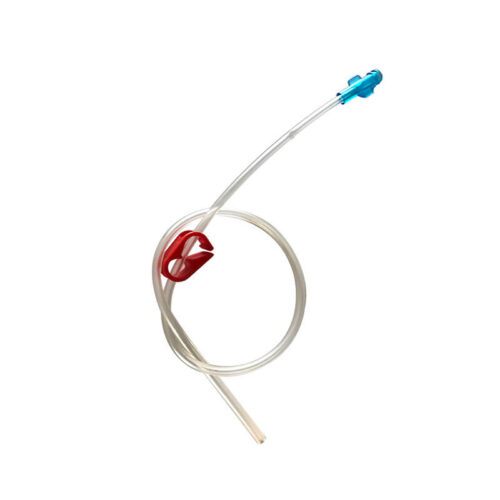

- Assembling the Contacts: The contacts are another important part of the thermal circuit breaker and are used to open and close the circuit. Assembly machines can assemble contacts and other components to ensure they work properly in the circuit.

- Assembling the Coil Spring: The coil spring is another critical component in a thermal circuit breaker that controls the travel of the contacts. Assembly machines can assemble coil springs and other components together.

- Automatic control: Modern thermal circuit breaker assembly machines usually have an automatic control system, which can realize automatic assembly and improve production efficiency and product quality.

If you want to contact me, please email us.

Thermal Circuit Breaker Assembly Machine Introduction

A machine is a kind of machine equipment specially used for producing thermal circuit breakers. A thermal circuit breaker is a switching device used to protect circuit safety. It can quickly cut off the circuit when overload, short circuit, and other faults occur in the circuit, so as to protect the circuit equipment from being damaged.The machine mainly includes automatic feeding, automatic assembly, automatic welding, and other processes, which can realize efficient automatic production of thermal circuit breaker production lines, improve production efficiency and product quality, and reduce production costs.At the same time, the machine also has the advantages of high automation, high production efficiency, and low production cost, and is widely used in the electronics manufacturing industry.

Reviews

There are no reviews yet.