Syringe Assembly Machine Feature

- The syringe assembly machine can assemble various prefilled flushing syringes.

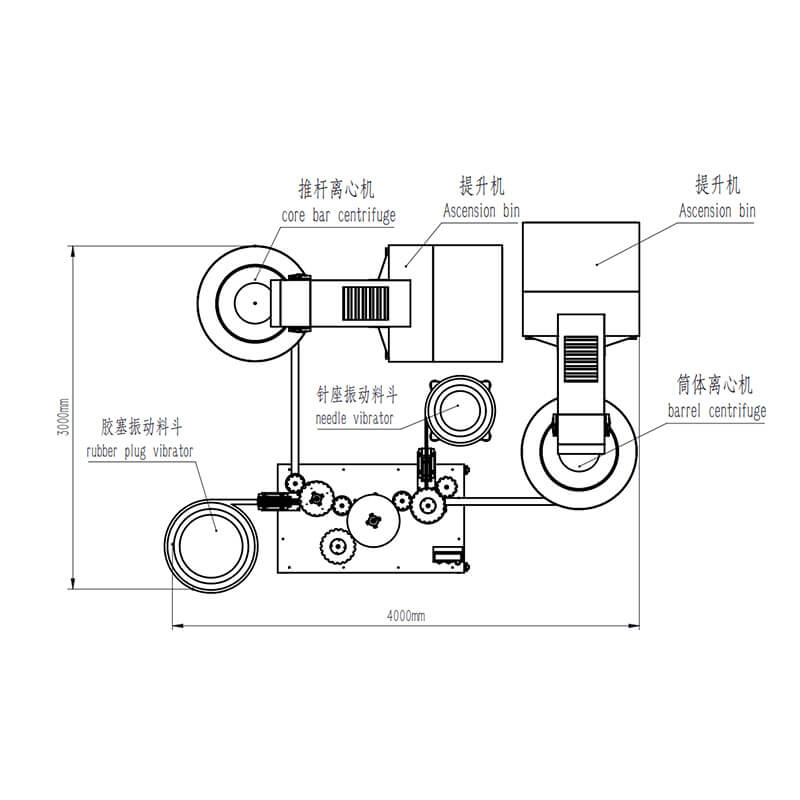

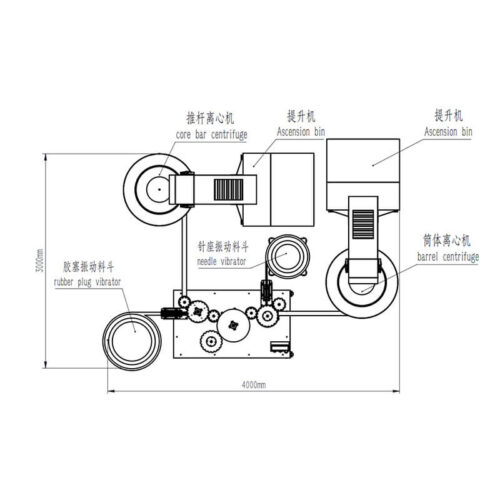

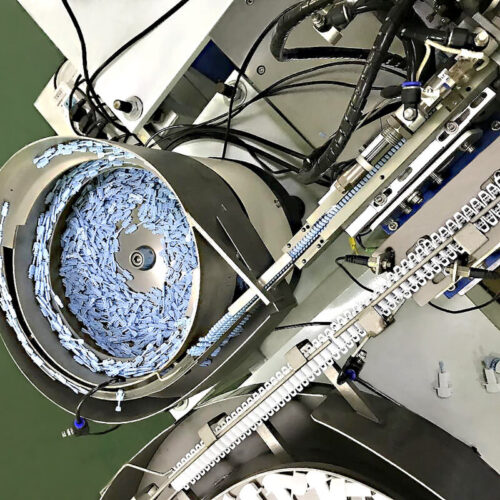

- The syringe making machine automatically loads and assembles all parts of the syringe with a vibrating plate or a loader.

- The syringe assembly machine is equipped with a safety cover, which stops running when opened, eliminates operating risks, reduces noise, and prevents dust.

- The syringe assembly equipment has a Mitsubishi inverter, PLC control, and photoelectric monitoring.

- The syringe assembly machine has the characteristics of automatic stop when there is no material, automatic start when feeding, etc., with fast assembly speed and stable performance.

- The syringe manufacturing machine uses stainless steel as the main body of the machine, which is rust-proof and pollution-free.

- The disposable syringe assembly machine can continuously produce 20 hours a day.

Featured Video

Conclusion

We have worked on several projects and if you wish you can send us your ideas or known parameters of your machine.

So our team can be ready to discuss functional specifications.

We will customize the most suitable plan for you according to your needs.

If you would like to inquire about information, please get in touch with us by email.

About Syringe Assembly Machine

What is a syringe assembly machine?

A syringe assembly machine is a kind of automatic syringe assembly equipment.

The syringe manufacturing machine completes the various

assembly steps of the syringe through a series of precise mechanical

and electronic operations, to ensure that the entire production process

These assembly steps include assembling the needle, installing the

piston, and filling the liquid medicine.

A disposable syringe making machine is used in the medical device

manufacturing industry, providing a reliable solution for producing high-quality, specification-compliant syringes.

What are the advantages of a syringe assembly machine?

Improve production efficiency:

A syringe assembly machine can complete assembly tasks with high

speed and high precision, far exceeding the efficiency of manual assembly.

Improve product quality:

The single-use syringe manufacturing machine ensures that the

assembly process of each syringe meets the standard requirements

through precise mechanical and electronic control.

This ensures the consistency and quality of the syringes, improving

product reliability and safety.

Reduced labor costs:

The automatic syringe assembly machine process reduces the need

for manual labor, thereby reducing labor costs.

Improved working environment and safety:

The operation of the syringe assembly machine reduces manual

operations and exposure to hazardous substances, improving the working environment and operator safety.

It is able to operate under strict hygienic requirements, reducing

the risk of cross-contamination and ensuring the hygienic and

quality of products meets the requirements.

Data recording and traceability:

The syringe assembly machine has data recording and traceability

functions, which can record production data, operating parameters, and quality indicators in real time.

The price is right:

The syringe making machine price is the disposable syringe manufacturing plant cost.

How to maintain the syringe assembly machine?

Maintenance of a disposable syringe manufacturing machine needs regular cleaning, lubrication, and inspection.

Cleaning can prevent dust and impurities from affecting the

machine, lubrication can ensure the normal operation of a syringe

assembly machine parts and inspection can find and repair potential problems in time.

Besides, worn parts should be replaced and any necessary

calibrations should be performed, as recommended by us.

Reviews

There are no reviews yet.