Fish Bone Thread Barb Suture Cutting Machine

Main Features

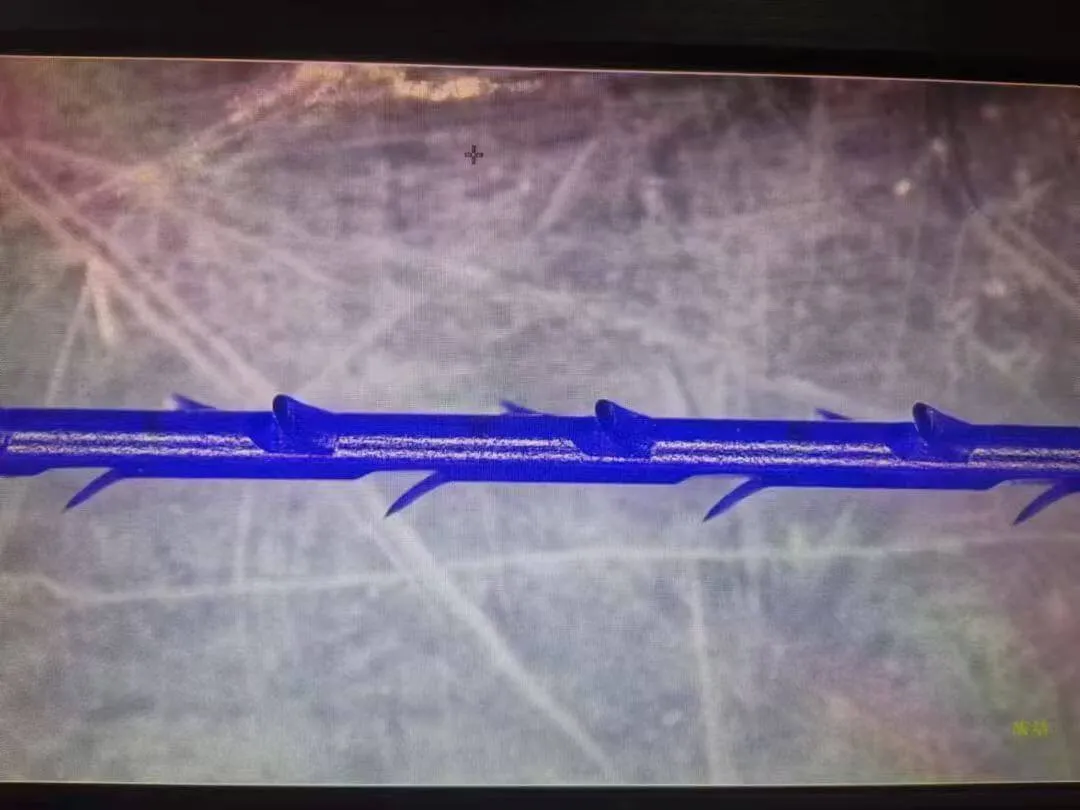

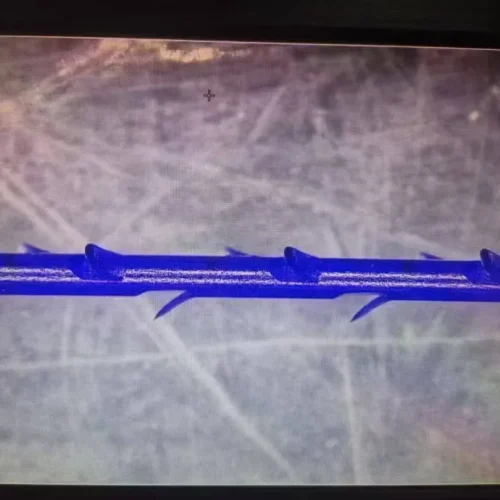

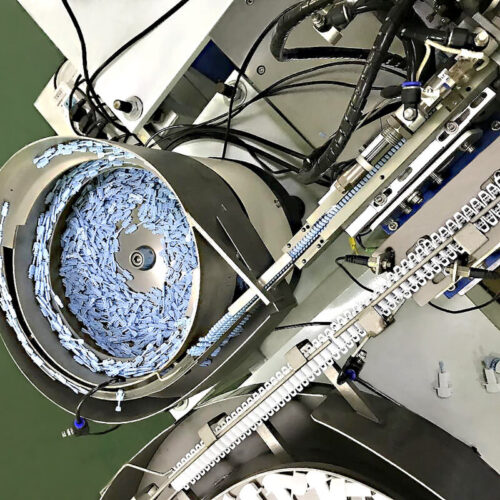

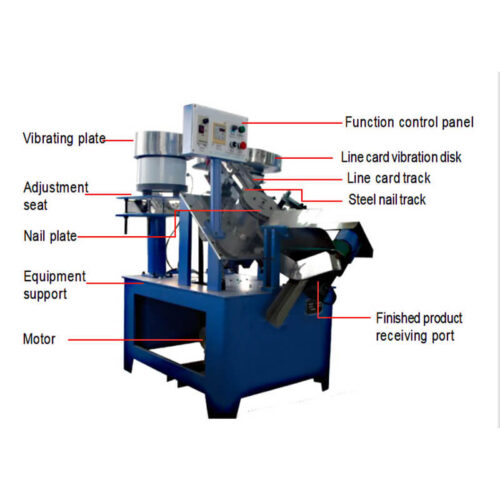

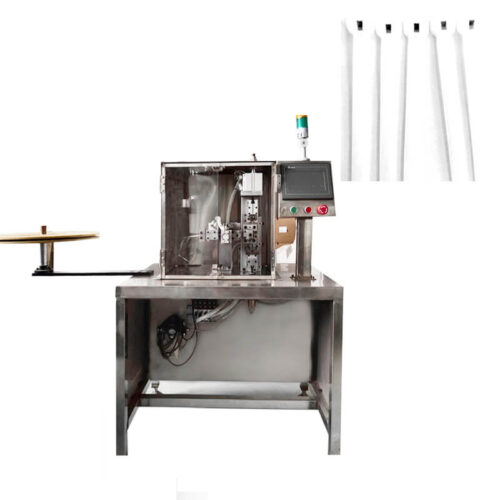

The Fish bone Thread Barb Suture Cutting Machine for medical sutures is mainly composed of a feeding mechanism, a rotating wire pulling mechanism, and a cutting knife mechanism. Fish bone Thread Barb Suture Cutting Machine adopts a double knife holder method to significantly enhance the efficiency of barb cutting. The Fish Bone Thread Barb Suture Cutting Machine offers a versatile cutting process package, enabling parallel and spiral barb cutting and accommodating customized cutting processes.

Fish Bone Thread Barb Suture Cutting Machine

Main Functions

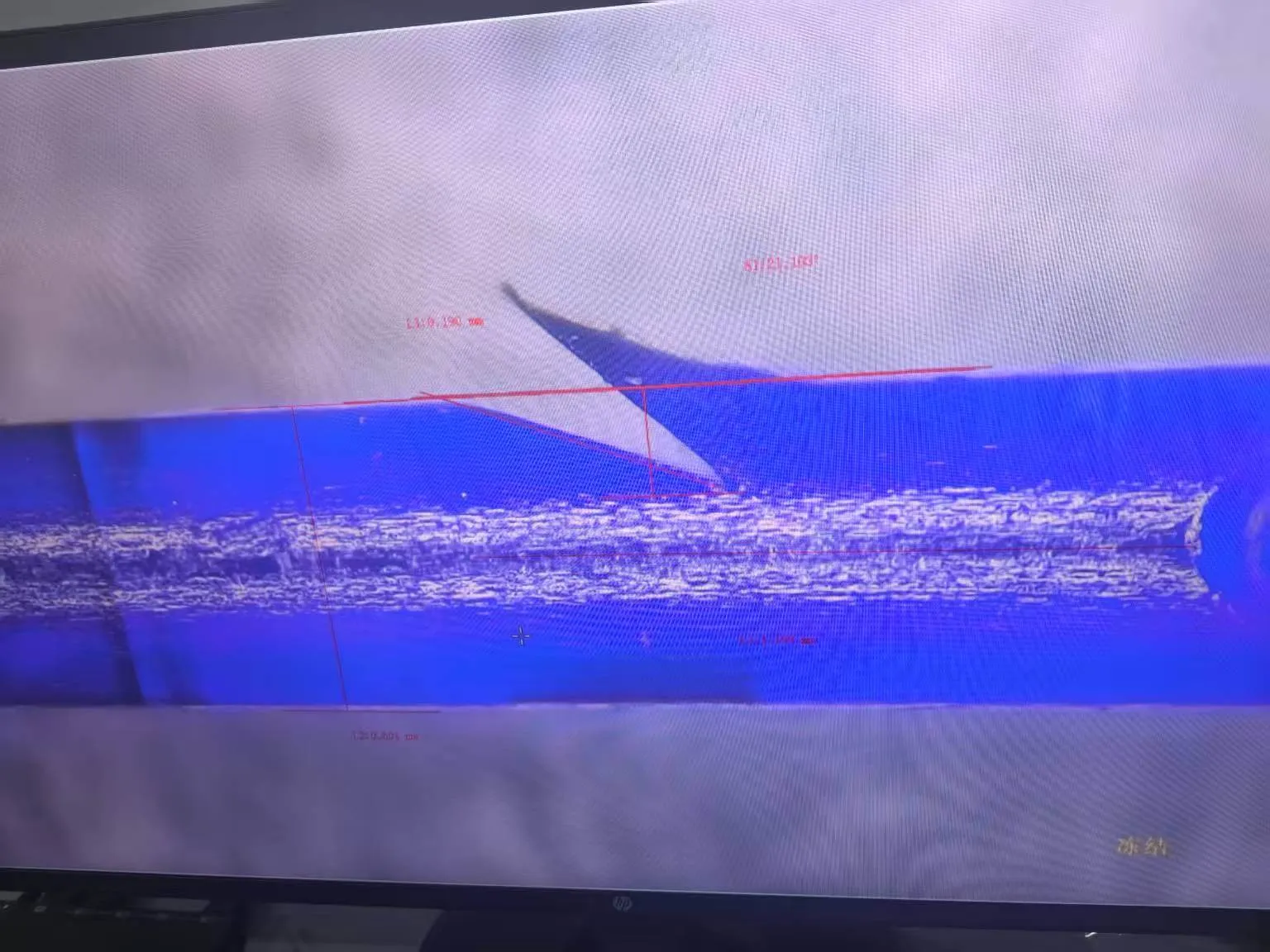

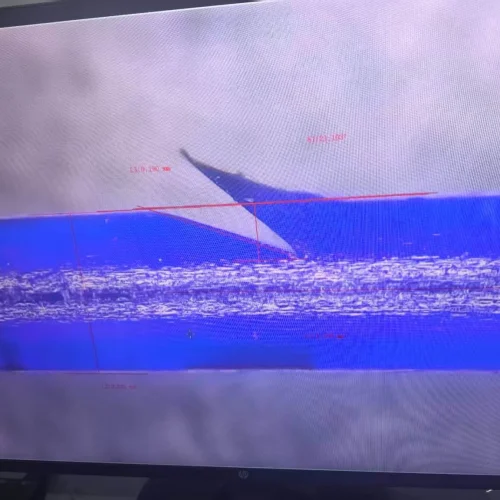

The double knife holder method is employed as an innovative solution to significantly enhance the efficiency of cutting barbs, streamlining the process, and ensuring higher productivity.This advanced method is complemented by a self-developed multi-axis motion control system that boasts both high precision and remarkable flexibility. This system ensures that each movement during the cutting process is executed with utmost accuracy while maintaining the versatility to adapt to various cutting requirements.Moreover, the system comes equipped with an extensive array of cutting process packages, designed to cater to diverse needs while keeping the operational procedure straightforward and user-friendly. This feature eliminates the complexity often associated with such sophisticated machinery, allowing operators to seamlessly transition between different tasks.Compatibility is another key strength of this system. It seamlessly accommodates suture wire cutting barbs with wire diameters ranging from 0.15mm to 0.7mm. This wide compatibility means that the system can adapt to different wire diameters without the need for time-consuming mold changes, further enhancing operational efficiency.To further bolster its capabilities, the system incorporates a highly integrated micro-vision system. This innovative feature enables real-time observation of the cutting effect on the barbs, providing immediate feedback and ensuring the highest quality of cuts. This real-time monitoring helps in detecting any imperfections or deviations promptly, allowing for immediate corrective actions.For enhanced ease of use, the system features one-button switching between production mode and tool setting mode. This allows operators to seamlessly transition between tasks without the hassle of navigating complex menus or interfaces. Additionally, the tool setting visual assistance system significantly diminishes the complexity of tool setting, making the entire process more intuitive and less error-prone.Overall, the system’s design emphasizes ease of operation, precision, and adaptability, making it an invaluable asset for any application requiring efficient and high-quality cutting of suture wire barbs.

Fish Bone Thread Barb Suture Cutting Machine

Fish Bone Thread Barb Suture Cutting Machine

Specification

| Device size | 2350mm*950mm*1900mm |

| Equipment voltage | AC220V 50Hz |

| plant capacity | 7.5kw |

| Equipment pressure | ≥0.6Mpa |

| weight of equipment | 1500kg |

| lay out | 2.5mx2.6 m x2.2m |

| Type of suture line | PDO and PP OD 0.15,0.7mm |

| thread size | 100MM-2000MM(customized) |

| speed | Single-angle barbs are greater than or equal to 0.9s perbarb(Depending on the material of the sutureand other stress conditions) |

| Number of cutting blades | Double knife holder |

| Razor type | Single-angle stab |

| Razorback arrangement | Parallel spines and spiral spines |

| The direction of the barbs | One-way barbs, two-way barbs |

| Tangentaccuracy | ±0.015mm |

| Angle, depth, distance, and return angle | customized |

| visualinspection | Visual knife, real-time monitoring of cutting effect |

Reviews

There are no reviews yet.