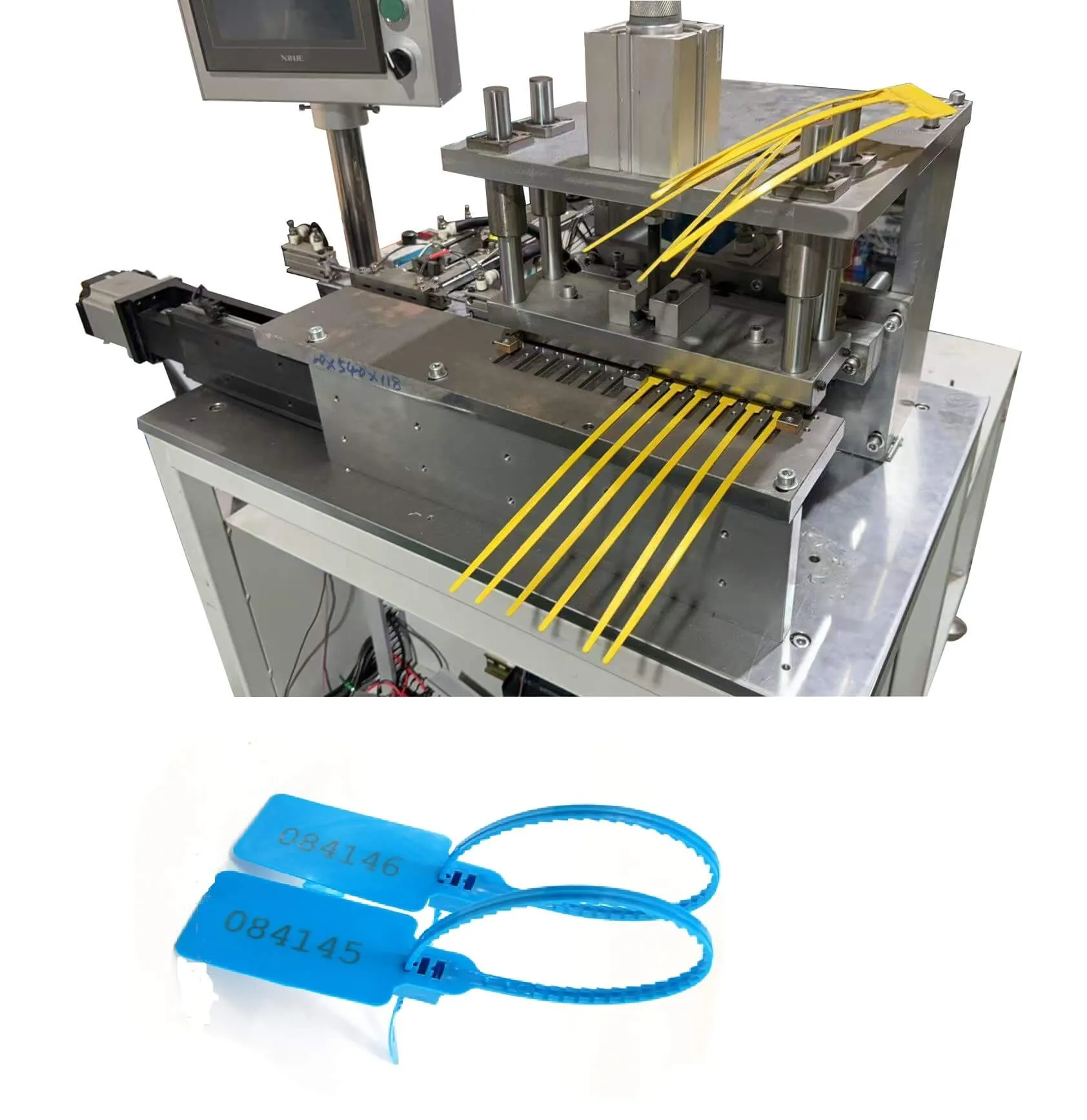

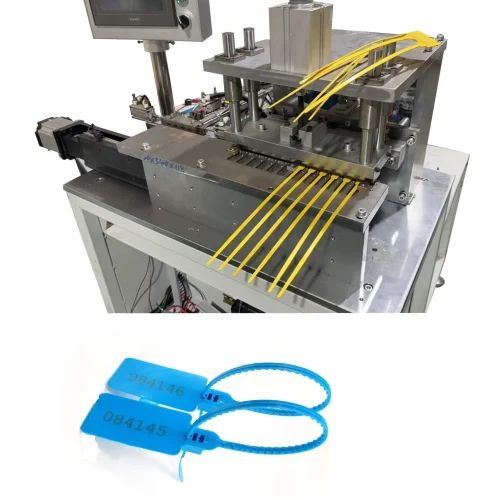

Security Seal making machine

Main Features

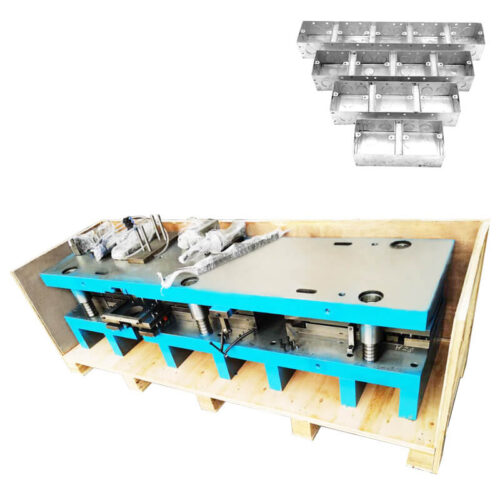

The safety seal assembly machine assembles the plastic cable tie, metal gasket, and lid by heat pressing or the ultrasonic method. It ensures that the finished product of the safety seal is firm, sealed, and perfect in appearance. The machine has 1-out-1 and 1-out-2 models. Customers can choose according to actual conditions.

Security Seal making machine

Main Functions

Equipment Features

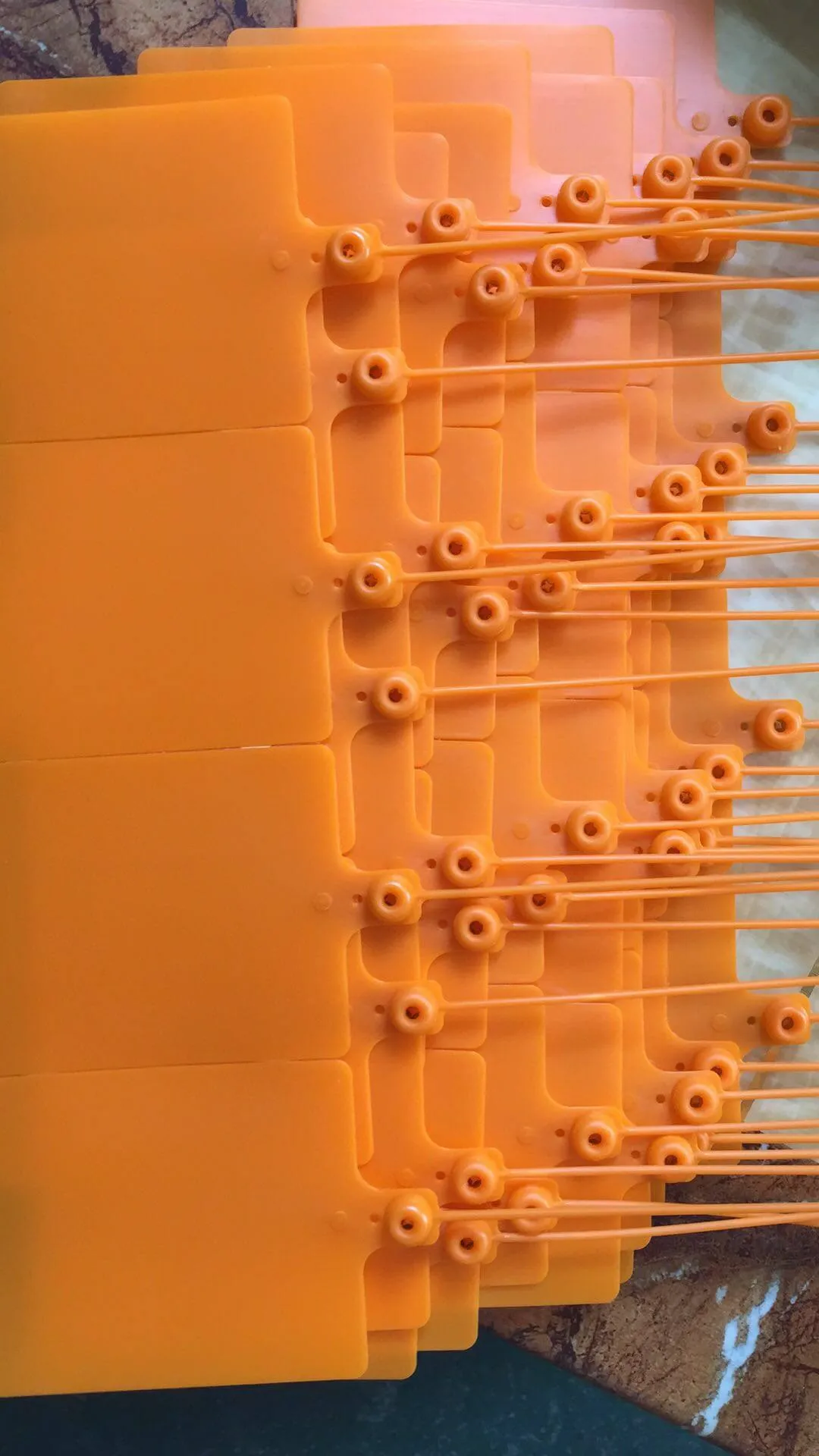

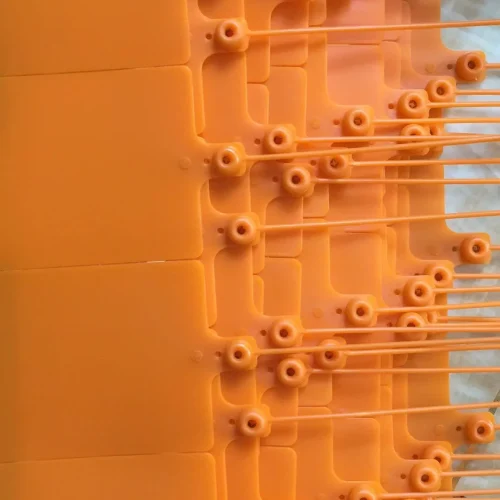

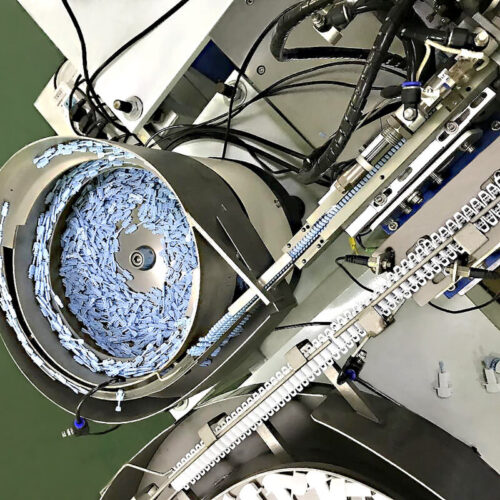

1. **Assembly method**:- Use heat pressing or ultrasonic technology for assembly to ensure a tight combination between components.- The heat sealing or ultrasonic heat sealing process is stable and reliable, suitable for components of different materials and thicknesses.2. **Productivity selection**:- Provide 1-out-1 and 1-out-2 styles to meet the different production needs of customers.- Customers can choose the appropriate style according to actual conditions to improve production efficiency.3. **Feeding method**:- A row of 10 cable ties requires manual feeding, which is simple and fast to operate.- Metal gaskets and lids are automatically fed through a vibrating plate to reduce manual intervention and improve the degree of automation.4. **Push-out mechanism**:- The machine uses a manipulator to push out the finished product to ensure the continuity and stability of the assembly process.- After the manipulator is launched, the machine immediately enters the next round of assembly to improve production efficiency.5. **Labor saving**:- The machine can reduce at least 3 manpower and significantly reduce production costs.- High degree of automation, reducing the labor intensity of employees and improving production safety.6. **Quality assurance**:- The machine uses high-quality ultrasonic and accessories to ensure long-term stable operation.- The combination of components is firm and reliable, and the finished product has excellent sealing performance and a perfect appearance.Application scenarioThis safety sealing assembly machine is widely used in product assembly fields that require high sealing and firmness, such as electronic products, automotive parts, medical devices, etc. Through automated assembly, production efficiency is improved, production costs are reduced, and the quality of finished products is guaranteed.After-sales serviceWe provide comprehensive after-sales service, including equipment installation and commissioning, operation training, repair and maintenance, etc. Ensure that customers can get timely solutions to problems encountered during use to ensure the smooth progress of production.SummaryThe safety sealing machine has become the preferred equipment for many companies to improve production efficiency and reduce production costs due to its high efficiency, automation, stability, and reliability. We sincerely invite you to visit us, learn more about the machine, and explore cooperation opportunities together.

Reviews

There are no reviews yet.