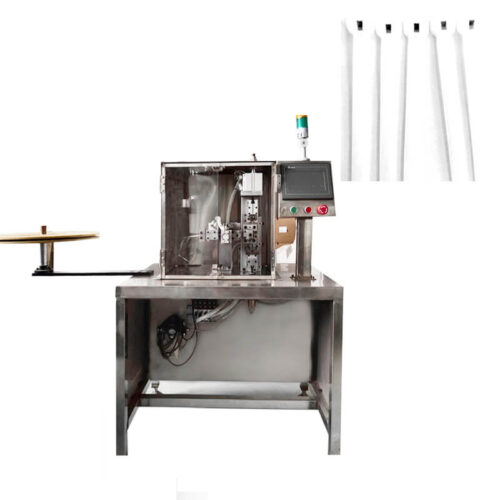

Fish Bone Thread Molded Barb Making Machine

Main Features

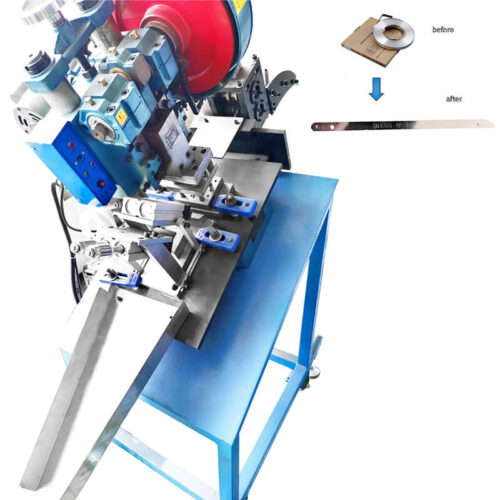

This fishbone thread molded machine is a special fishbone wire embossing forming system developed for the high-end medical device industry. It integrates precision machinery, intelligent control, and online visual inspection technology, and is used for continuous high-precision processing of fishbone-shaped barbs on surgical sutures. The system adopts a modular architecture, realizing an automated process from material supply to precision tension control, multi-station embossing, fixed-length cutting, and finished product collection, meeting the strict requirements of the ISO 13485 medical device quality management system for process stability. The fishbone thread molded machine system adopts a multi-threaded concurrent architecture and is equipped with a self-developed intellectual property process logic editor to decouple motion control, process logic, and workflow scheduling.

Specification

| Size:L1262mm x W480mm x H790mm |

| Weight:100Kg |

| Lay out:1.3m x0.8m x 1m |

| Power :AC220V±10%50Hz ,1.8kW |

| Air:≥0.6MPa |

| wire diameter-0#to 1#sutures(USP standard) |

| Finished length:≥50mm |

| speed: 1.2s/pcs |

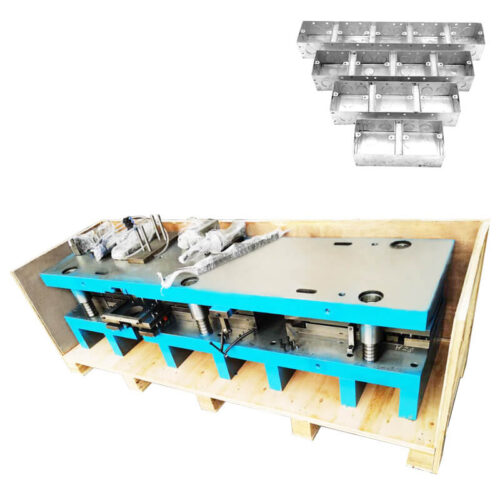

| Imprinting method: high precision CDD Hook type: fishbone hook shape Molds witching mode: convenient modular design |

Fish Bone Thread Molded Barb Making Machine

Main Functions

●High-precision embossing processAdopt high-precision mold forming technology to ensure the consistency of fishbone wire.Applicable to sutures with specifications of 3-0# to 1#.Support a dynamic tension compensation algorithm to adapt to the differences in mechanical properties of sutures of different materials.●Modular intelligent systemThe feeding, embossing, and cutting mechanisms adopt a standardized and modular design to meet the GMP modular assembly requirements of the medical device industry.●Real-time quality monitoringAdopt industrial-grade microscope lenses with a magnification of more than 50 times to monitor the perforation quality in real time.●Flexible production platformThe mold replacement time is less than 5 minutes, and it is compatible with multi-needle process expansion to meet the production needs of small batches and multiple varieties.The fishbone thread molded machine process database presets the process data of fishbone wires with specifications of 3-0# to 1#.

Reviews

There are no reviews yet.