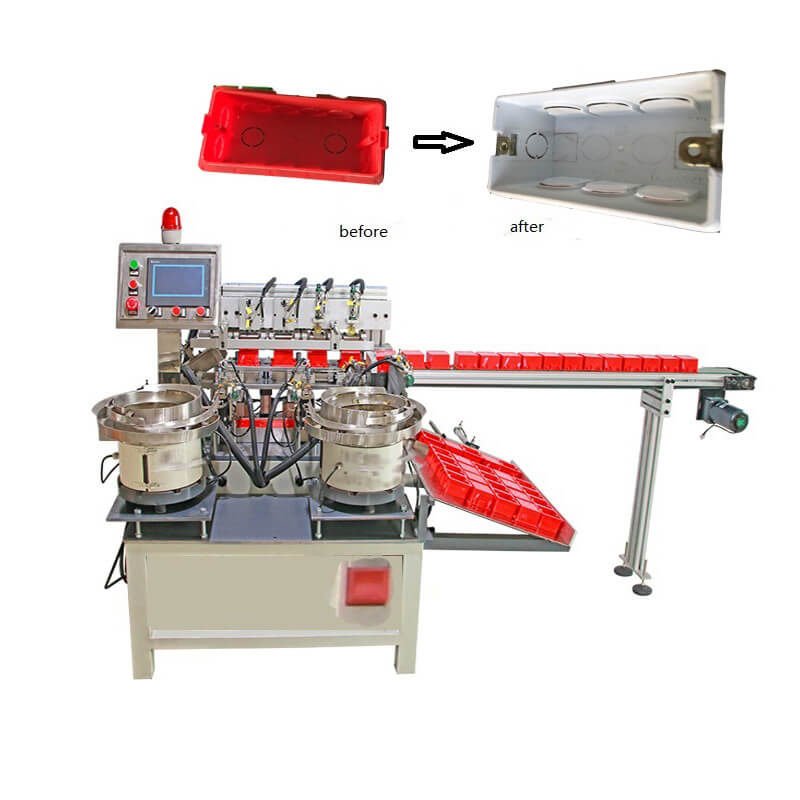

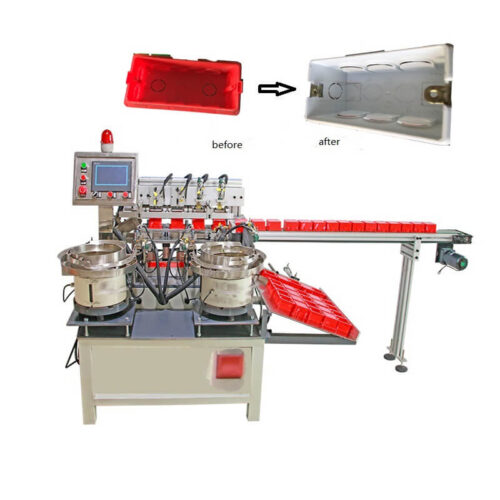

Junction Box Making Machine

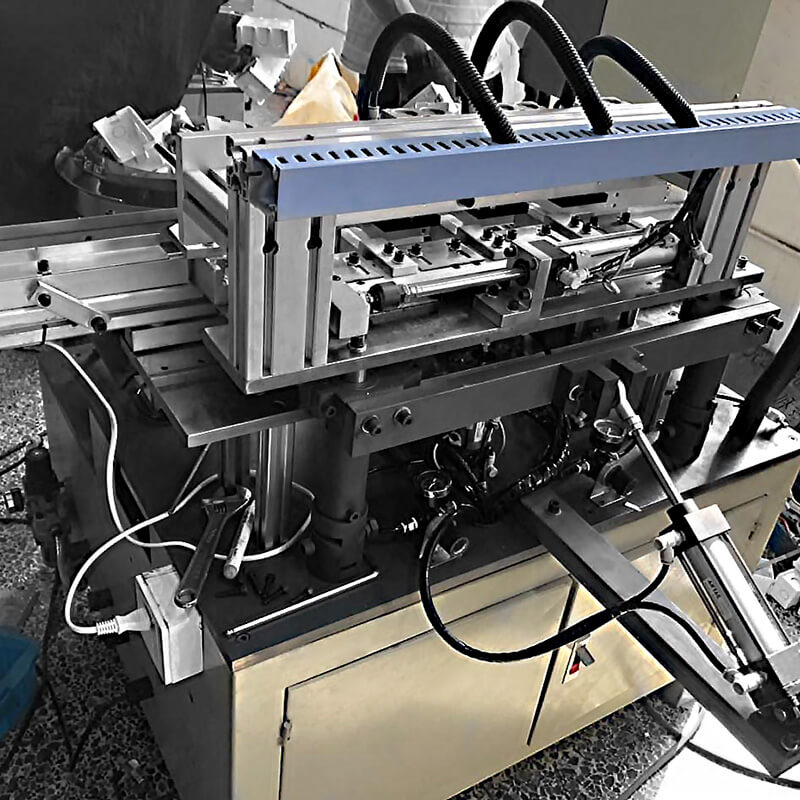

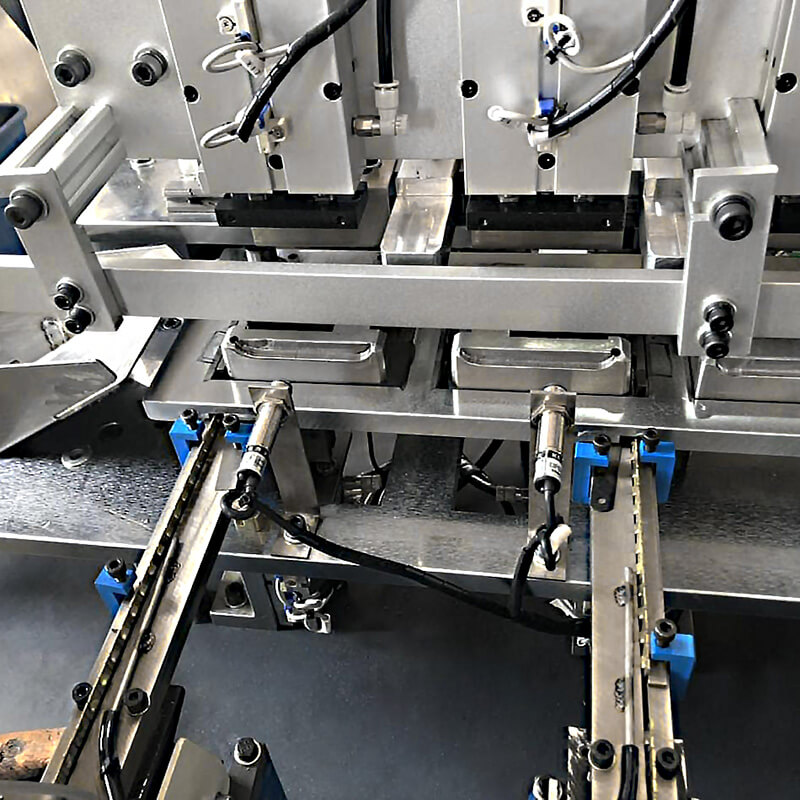

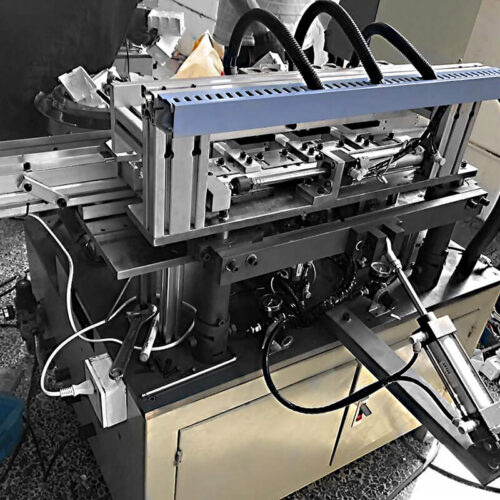

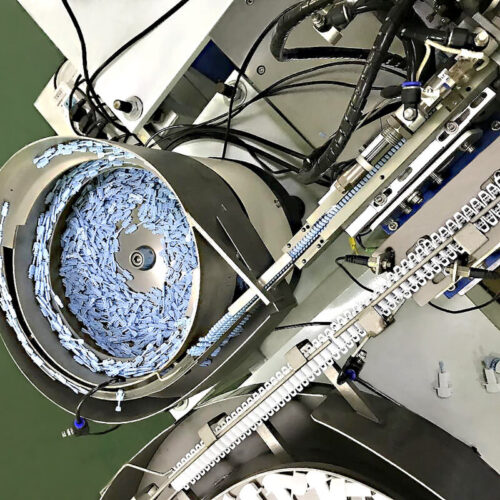

The assembly machine’s PLC systems are the heart of its automation, orchestrating intricate movements with meticulous accuracy. The programming flexibility of these controllers allows for easy customization to meet the diverse requirements of junction box designs, ensuring a tailored solution for every production need. The intuitive touch screens, featuring user-friendly interfaces, empower operators to effortlessly monitor and control the assembly process, reducing the learning curve and enhancing operational efficiency.

The integration of Taiwanese sensors, renowned for their precision sensing capabilities, ensures that every step of the assembly process is executed with utmost accuracy. These sensors detect even the slightest deviations, enabling immediate corrective actions to maintain the highest standards of quality control. Coupled with the use of durable cylinders, known for their reliability and longevity, the machine stands the test of time, minimizing downtime and maximizing productivity.

Moreover, the adoption of such premium components underscores the manufacturer’s commitment to sustainability. By selecting materials and parts that are built to last, the junction box assembly machine contributes to reducing waste and environmental impact, aligning with modern-day eco-conscious manufacturing practices.

In summary, the junction box assembly machine represents a pinnacle of technological advancement, where the harmonious blend of cutting-edge PLC systems, intuitive user interfaces, and premium components from Taiwan creates a powerful synergy. This synergy not only revolutionizes the production process but also guarantees the delivery of junction boxes that are not only highly efficient but also enduring, setting new benchmarks for quality and performance in the industry.

Featured Video

Conclusion

We have worked on several projects and if you wish you can send us your ideas.So our team can be ready to discuss functional specifications.We will customize the most suitable plan for you according to your needs.If you would like to inquire about information, please get in touch with us by email.

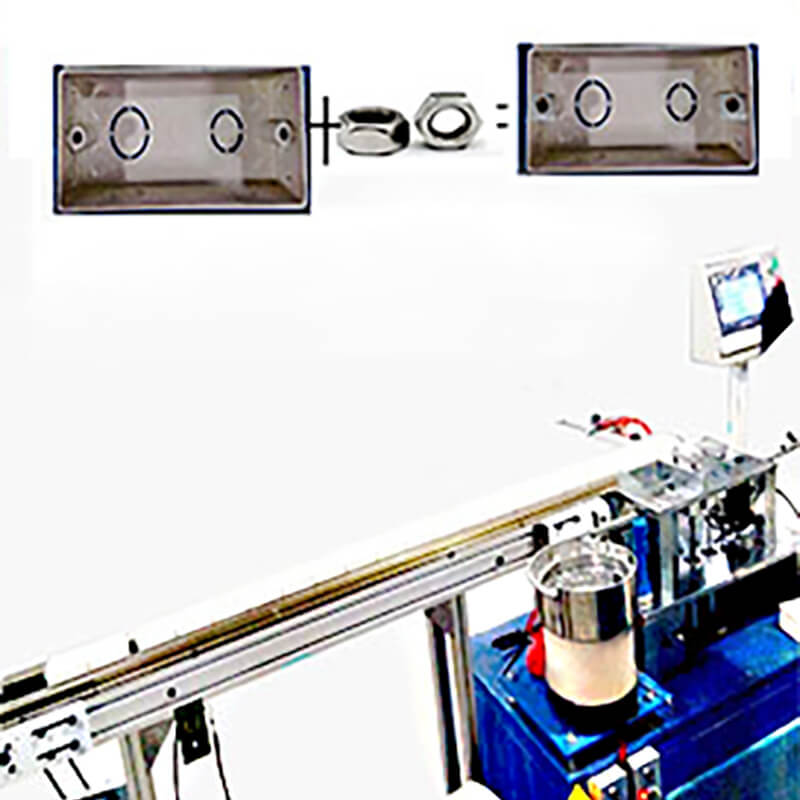

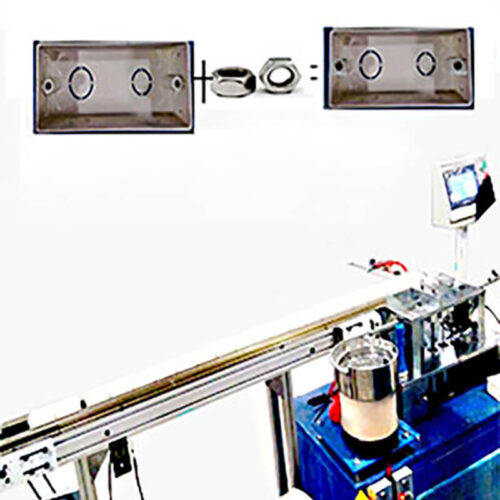

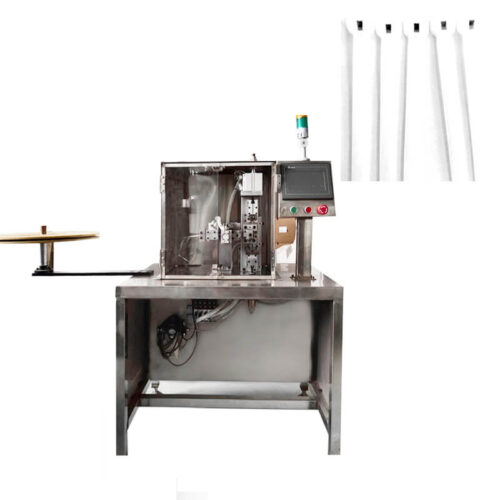

About Junction Box Making Machine

Efficient production: It can automate continuous production and improve production efficiency.Precise Forming: It can make high-precision wire box molds to ensure product quality and consistency.Diversified production: The mold can be replaced according to demand to adapt to the production of wire box molds of different shapes and sizes.

The working principle of the plastic junction box making machine is basically heating and injecting plastic granules or granulated molten materials into the mold, then cooling and forming, and finally getting the required wire box mold.

Electrical junction box making machine is widely used in the wire box production industry.Wire boxes are devices used to install and protect wire connections, and are commonly used in construction, electricity, communications, and other fields.

Reviews

There are no reviews yet.