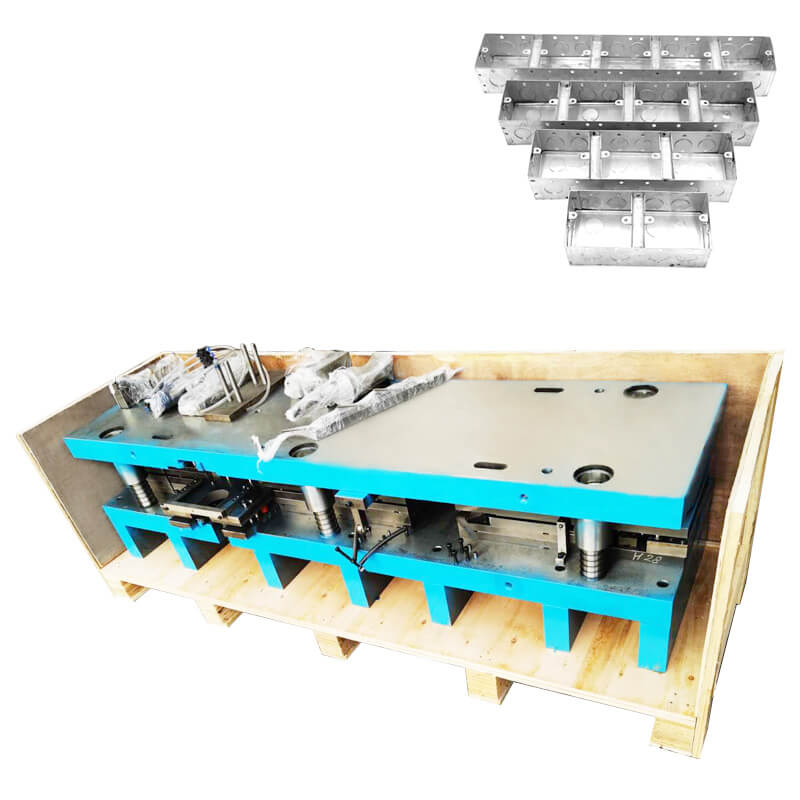

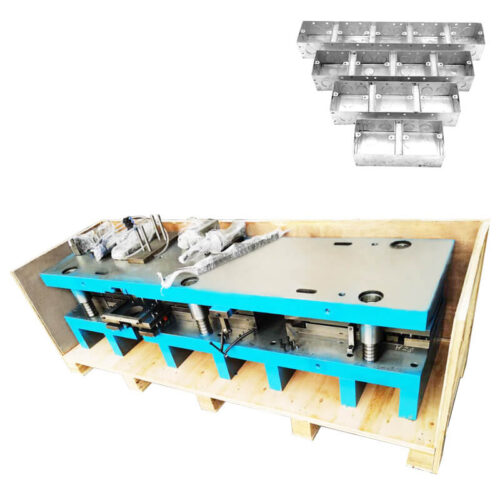

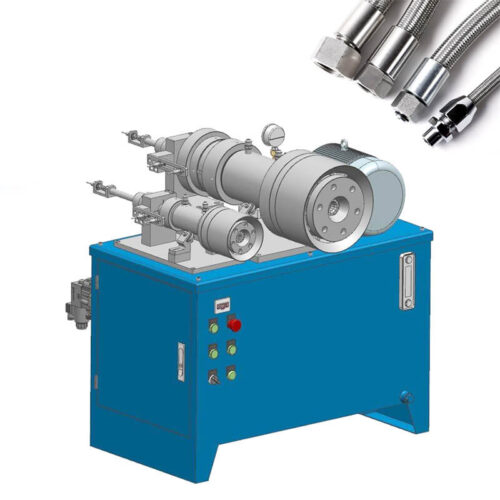

Metal Junction Box Molding Machine

Main Features

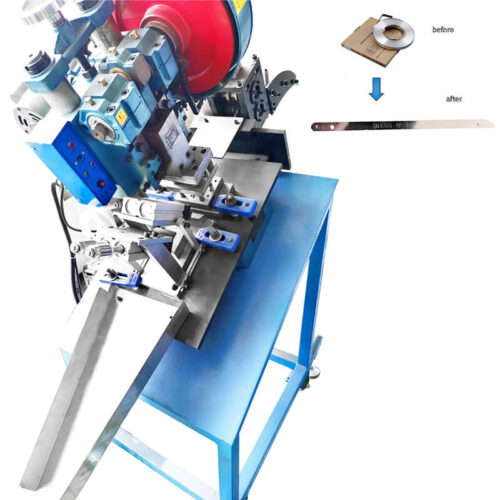

The Metal Junction Box Molding Machine is widely used in the Indian and African markets. We have a complete production line, from punches to grinding tools to accessories. When the press is die-casting, the vibration plate is used to transport the screws and other accessories to the machine to complete the whole process. Without other assembly machines and equipment, it can be directly packaged and sold. 72 * 72 * 47, 72 * 156 * 47, 72 * 243 * 47, etc. can be made.

Technical Parameters

| Speed | 60Pcs Per Minute |

| Measurement | 1.2x2x3M |

| Delivery Time | 65Days |

| Guarantee | 1Year |

| Power | 380V |

| Certificate | Ce |

| Package | Wooden Box |

| Hs Code | 8479899990 |

| Driven Type | Electronics |

| Machine Name | Metal Junction Box Mold Machine |

Metal Junction Box Molding Machine Main Functions

- Automatic Feeding: The forming machine is able to automatically feed sheet metal into the machine for processing. By adopting an automatic feeding system, the molding machine can increase production efficiency and reduce labor costs.

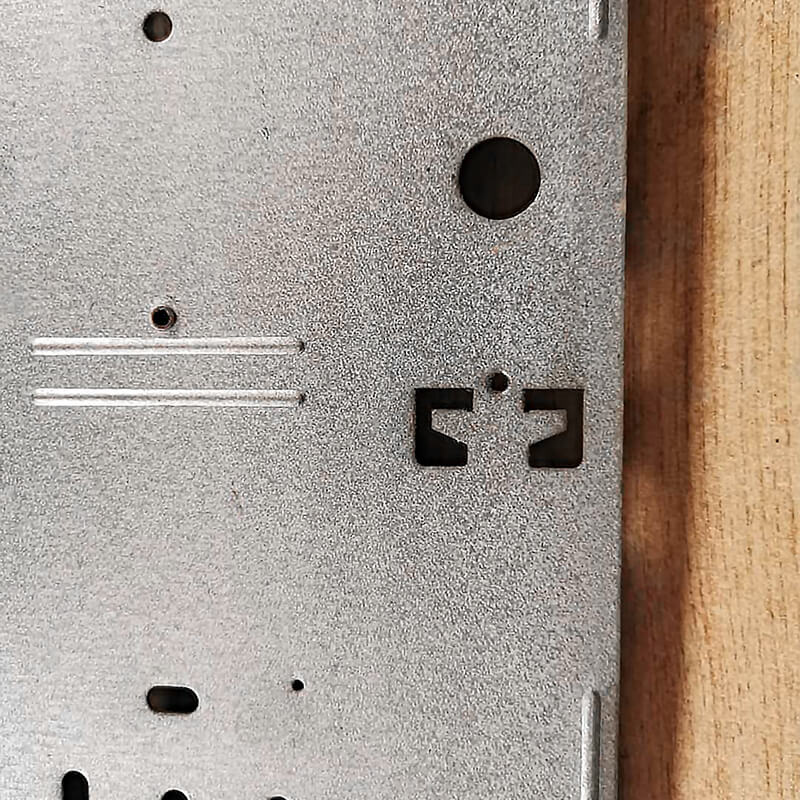

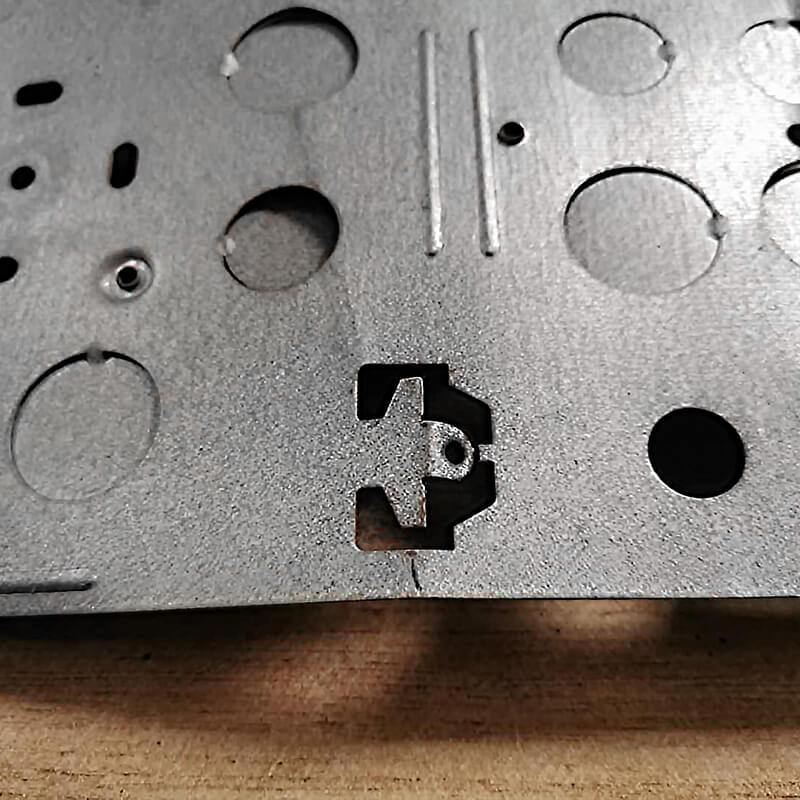

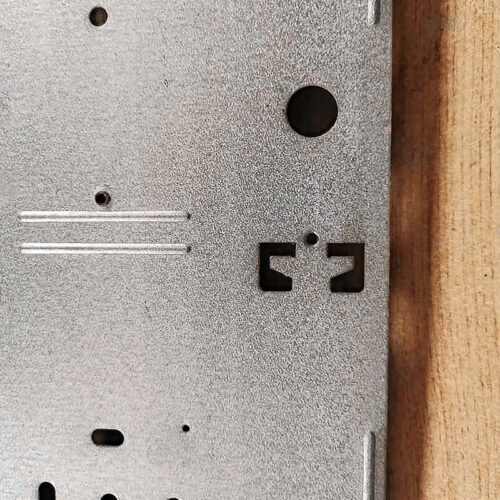

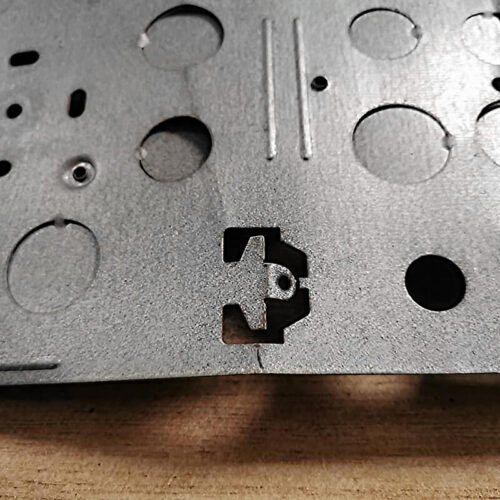

- Forming of the sheet metal: The forming machine can process sheet metal into parts with specific shapes. Many different processes can be used in the forming process, such as shearing, bending, punching, etc.

- Automatic cleaning: The forming machine can automatically clean the metal sheet to ensure the surface finish and quality of the processed parts.

- Automatic painting: The forming machine can automatically spray and paint the metal sheet to enhance the surface corrosion resistance and aesthetics of the parts.

- Automatic folding: The forming machine can automatically fold the metal sheet to increase the strength and stability of the parts.

- Automatic welding: The forming machine can automatically weld the metal sheet to make the parts have higher strength and stability.

- Automatic labeling: The molding machine can automatically identify and label parts to facilitate the traceability and management of parts.

Metal Junction Box Molding Machine Production Line

- Raw material processing: processing metal sheets or wires into required junction box components, such as box body, cover, socket, etc.

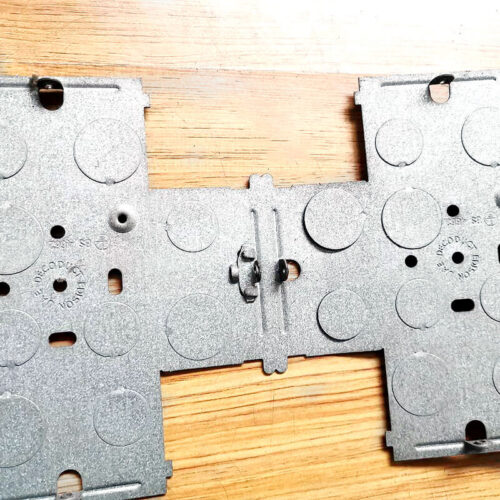

- Forming: Forming a metal material using a forming machine, such as bending a flat plate into a box.

- Welding: Use a welding machine to weld the various parts of the junction box.

- Surface treatment: use a spraying machine to carry out surface treatment on the junction box, such as painting, etc.

- Assembly: Assemble the welded parts to form a finished product.

- Inspection: The finished product is inspected to ensure it meets quality standards.

- Packaging: The finished product is packaged and ready for shipment.

Reviews

There are no reviews yet.