Plastic Bolt Bearing making machine

Main Features

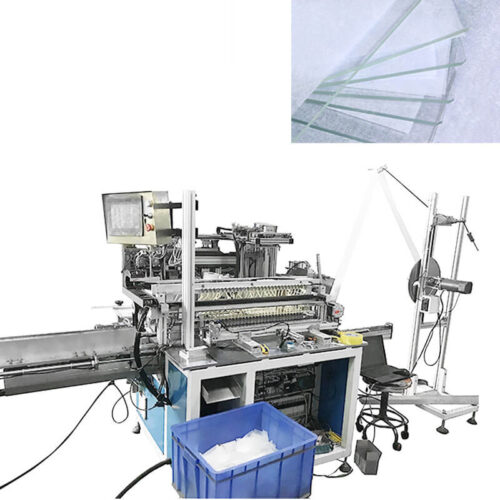

The Plastic bolt bearing making machine is an automated assembly equipment. It draws the plastic outer wheel and inner wheel together and bolts them together. The plastic bolt bearing making machine is the best choice for furniture factories and hardware factories. Our machine can reach 20 products per minute. The use of a soundproof cover can ensure a quiet working environment without generating pollution. One engineer can take care of 5 machines at the same time.

Technical Parameters

Plastic Bolt Bearing making machine

Main Functions

The Drawer Wheelie Assembly Machine is a highly automated production machine designed for efficient and precise assembly tasks. It skillfully and precisely assembles the plastic outer wheels with the inner drawer core, bolts, and other key components to ensure the high quality and durability of the finished product. This assembly machine is not only ideal for furniture factories to enhance production efficiency, but also a powerful assistant for hardware factories and other manufacturing sectors to optimise production processes and enhance competitiveness.

In terms of production efficiency, the drawer wheelie assembly machine shows excellent performance. Its efficient assembly process enables the output of up to 20 products per minute, which greatly enhances the overall capacity of the production line. At the same time, in order to create a more comfortable and quiet working environment, the equipment is equipped with a soundproof cover, effectively reducing the noise pollution, to ensure the physical and mental health of the operators.

The drawer skate assembly machine also excels in terms of ease of operation. One engineer can easily manage and monitor the operating status of five machines, thanks to its intuitive and easy-to-use control system. The machine adopts Mitsubishi’s high-definition display, which is not only clear and colourful but also has a user-friendly interface, enabling engineers to quickly grasp the machine’s operating conditions and make the necessary adjustments.

In terms of hardware configuration, the drawer skating assembly machine is also not to be underestimated. It uses high-quality cylinders and fittings from Airtac, as well as connectors from other excellent brands to ensure the stability and durability of the equipment. The synergistic effect of these high-quality components enables the machine to maintain excellent performance in a long-time, high-intensity production environment.

In addition, the compatibility of the drawer wheelie assembly machine is outstanding. It supports 220V or 380V voltage input, which can meet the electricity needs of different regions. If other voltages are required, customised transformers can be supplied to ensure that the machine can be connected to the local power grid.

In terms of operation mode, the drawer roller skate assembly machine adopts the feeding method of vibrating disc, which ensures the fast and accurate supply of parts. Meanwhile, the operation mode of mechanical arm clamping is carried out flexibly on the central round table, which not only improves the assembly efficiency but also ensures the stability and accuracy of the assembly process.

In order to guarantee the long-term stable operation of the equipment, we provide a one-year warranty period for the drawer roller skate assembly machine. During this year, we will provide free repair or replacement service if there is any non-man-made damage or failure of the equipment. In addition, we also provide round-the-clock technical support. Customers can contact us at any time when they encounter any problems in the process of use. We will be happy to answer your questions and provide assistance.

It is worth noting that in order to ensure the best performance and prolong the service life of the equipment, it is recommended to let the machine work for 20 hours a day and then rest for 4 hours. This ensures productivity and allows the equipment to be well-rested and maintained.

Plastic Bolt Bearing making machine

specifiation

Reviews

There are no reviews yet.