Valve Assembly Machine Features

Our cutting-edge valve making machine incorporates innovative features to streamline the assembly process seamlessly.

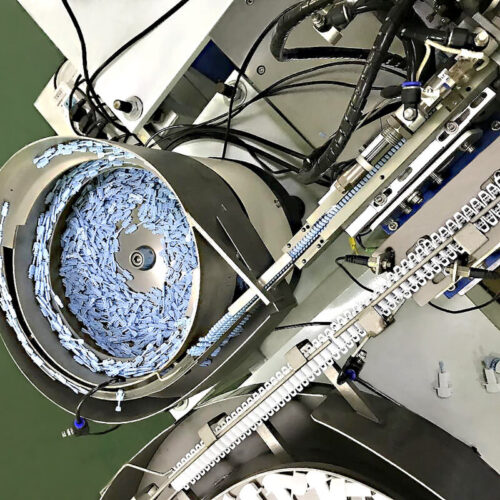

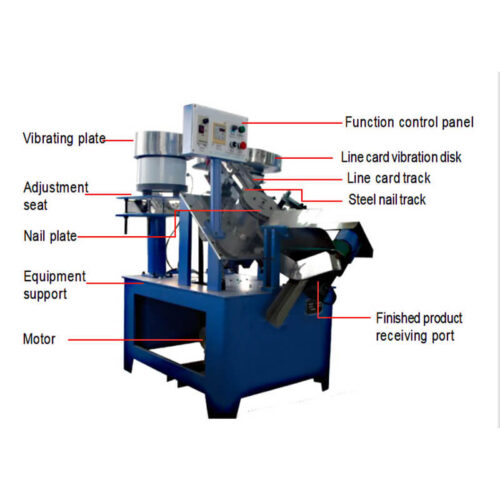

This valve manufacturing machine utilizes a profit-vibrating plate that efficiently transports the covers and joints to the central operating table.

It ensures smooth and precise movement, optimizing productivity and reducing manual handling.

Additionally, the machine incorporates an oil-dripping mechanism that precisely dispenses oil inside the product, enhancing its performance and functionality.

The assembly process is facilitated by a cylinder that effectively pushes the product into the joint, ensuring a secure and reliable connection.

Once the assembly is complete, a robotic hand delicately retrieves the finished product, further automating the process and increasing efficiency.

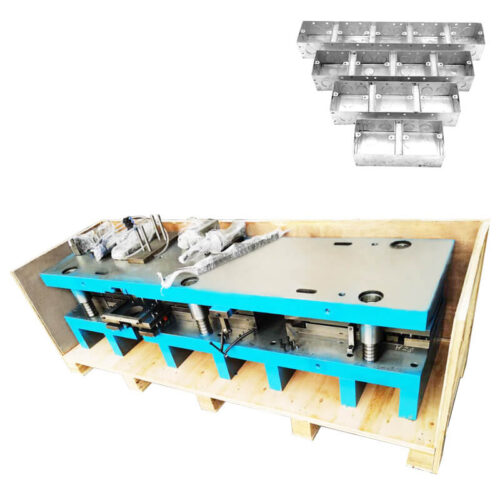

What sets our valve making machine apart is its versatility.

It enables the assembly of 3 to 6 different models of products without the need for parts replacement.

Featured Video

Conclusion

With our valve manufacturing machine, you can streamline your production process, optimize efficiency, and deliver superior valve products to your customers.

Moreover, our machine addresses the labor-related challenges faced by many manufacturers.

By automating the assembly process, it eliminates the need for extensive manual labor and overcomes the shortcomings associated with human error and fatigue.

Trust in our expertise and innovative solutions to meet your manufacturing needs.

Contact us today to learn more about our cutting-edge valve manufacturing machines and how they can benefit your business.

FAQ About Valve Assembly Machine

Yes, our machine is versatile and can accommodate various types of valves, allowing for efficient assembly of different models.

Reviews

There are no reviews yet.