According to the function, the types of assembly line equipment are divided into?

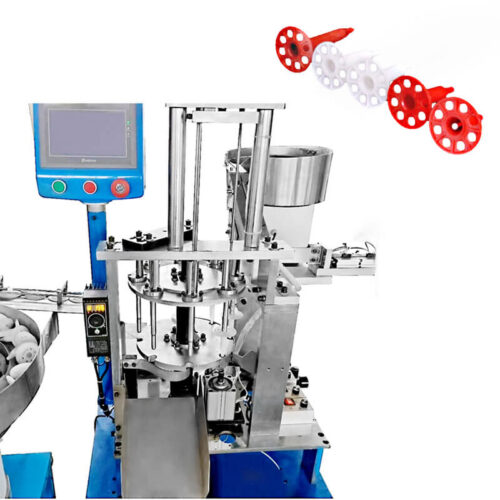

Automatic assembly machine:

An automatic assembly machine is a highly automated device that completes assembly tasks without human intervention.

It is able to perform multiple assembly steps through the use of advanced sensors, machine vision systems, and program controls, increasing production efficiency and accuracy.

Automated assembly machines are generally suitable for large-scale production environments, where the number of components is large and a high degree of consistency is required.

Key features of the automatic assembly machines include:

Highly automated: Automatic assembly machines can perform assembly tasks autonomously, reducing dependence on human resources.High-speed production: Automated assembly machines can complete assembly tasks at a high speed, improving production efficiency.High precision: With the help of advanced sensors and machine vision systems, automated assembly machines can achieve high-precision assembly to ensure product quality and consistency.Versatility: Automated assembly machines are often flexible and can accommodate different types and sizes of assembly tasks.

Semi-automatic assembly machine:

Semi-automated assembly machines combine manual operation and automation, requiring human participation in some assembly steps.It can provide more control and flexibility in complex assembly tasks while maintaining a certain level of automation.Semi-automated assembly machines are suitable for small to medium-scale production environments where human expertise and judgment may be required.

Key features of the semi-automatied assembly machine include:

Human involvement: Semi-automated assembly machines require operators to perform certain assembly steps, such as assembling complex components or making minor adjustments.Flexibility: Semi-automated assembly machines usually have high flexibility and can adapt to different assembly requirements and product changes.High precision: Although human involvement is required, semi-automated assembly machines are usually equipped with precise positioning tools and auxiliary equipment to ensure the accuracy and consistency of assembly.Adapt to small and medium-scale production: Semi-automated assembly machines are suitable for small and medium-scale production environments, in which it is necessary to take into account the advantages of production efficiency and manual operation.

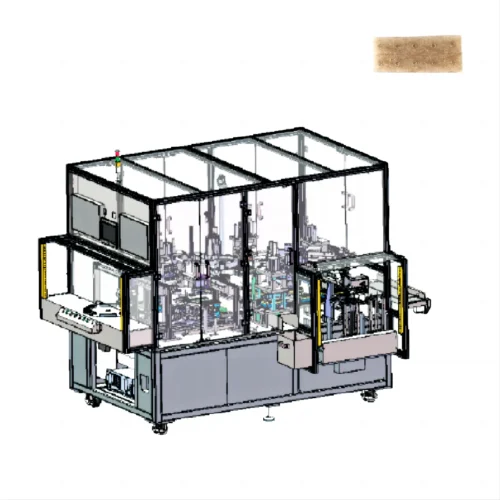

What is the working principle of an automated assembly machine?

Design The Assembly Process:

Before starting, formulate the assembly process according to the design requirements of the product. This involves determining the order, location, and connection of components.Write A Program:

Based on the assembly process, write a program to control the operation of the automated assembly machine. These programs can be implemented using programming languages, control software, or specific robot operating systems.

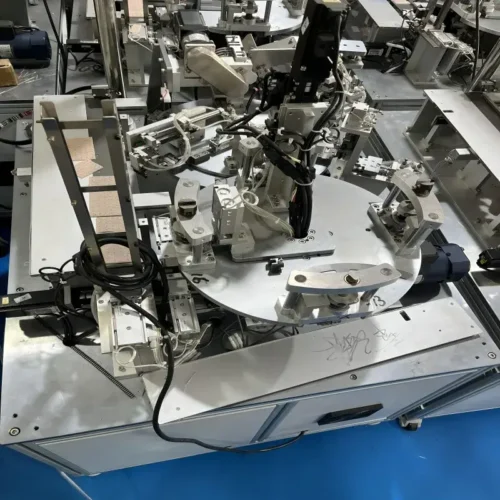

Sensors And Vision Systems:

Automated assembly machines are equipped with various sensors and vision systems to detect and monitor the position, quality and accuracy of parts. These sensors can be photoelectric sensors, pressure sensors, force sensors, etc., for real-time data acquisition.

Positioning And Positioning Systems:

Automated assembly machines use positioning systems to ensure precise positioning of parts. This can include the use of sensors, cameras, laser range finders, etc. to detect the position and orientation of parts in real time.

Robotic Manipulation:

Automated assembly machines often use robotic manipulation to perform assembly tasks. These robots can be articulated manipulators, parallel manipulators, sliding table mechanisms, etc., with high precision and flexibility, capable of performing precise movements.

Tools And Fixtures:

Depending on the requirements of the assembly task, automated assembly machines are equipped with various tools and fixtures. These tools can be screwdrivers, wrenches, pneumatic tools, etc. to connect, secure and handle components.

Control System:

The control system of the automated assembly machine is responsible for coordinating and controlling the operation of all components. It can include PLCs, motion controllers, touch screen interfaces, etc. to monitor and adjust the assembly process.

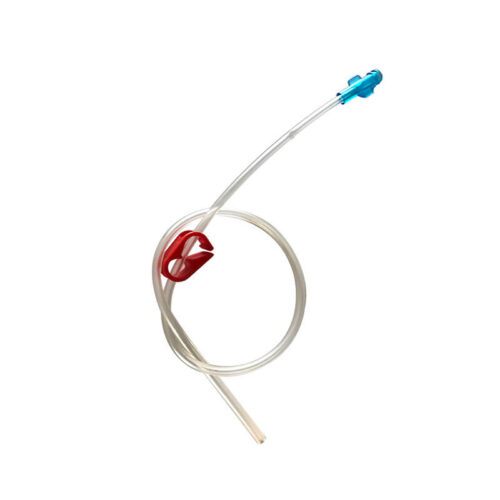

What is the relationship between automated assembly machines?

Custom assembly equipment refers to specialized machinery that is

tailored to meet specific assembly requirements or unique production processes.

Custom assembly equipment is versatile.

But, automated assembly equipment refers to

machinery that performs assembly tasks, with minimal human intervention.

Automated assembly equipment enhances productivity, reduces

labor costs, and ensures consistent quality in the assembly process.

Automated assembly machines are a specific type of automated

assembly equipment that is dedicated to performing assembly tasks.

Automated assembly machines excel in high-volume production

environments, where efficiency, reliability, and repeatability are crucial.

In summary, custom assembly equipment, automated assembly

equipment, and automated assembly machines all play integral roles in modern manufacturing processes.

What are the common types of custom assembly machines?

Common types of custom assembly machine include a high-speed assembly machine, an automated assembly machine, and a multi-station assembly machine.