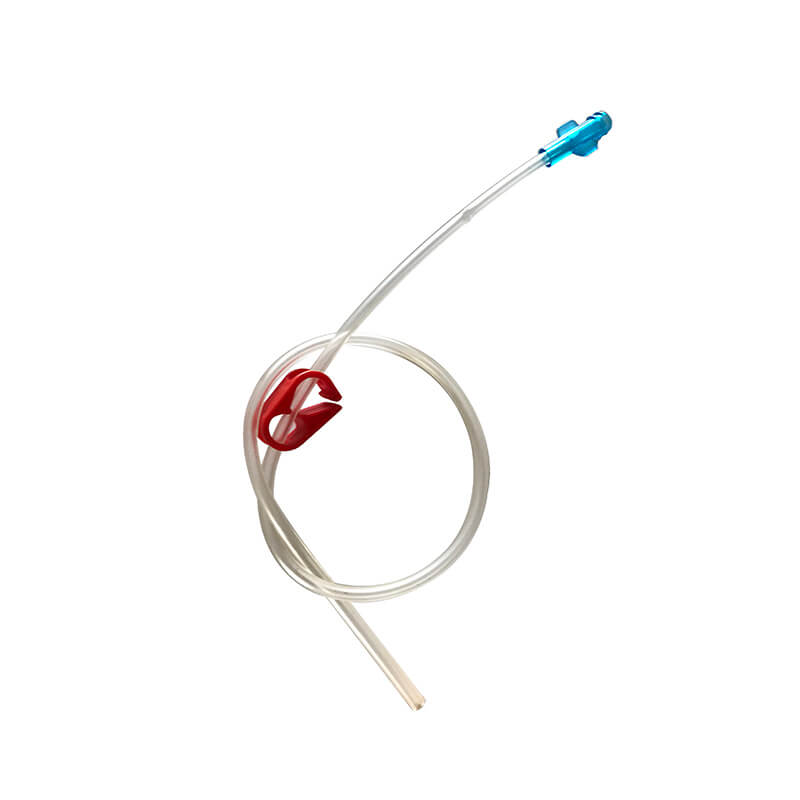

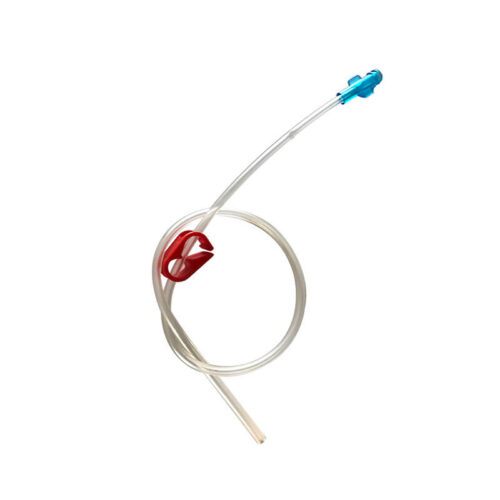

Scalp Vein Set Assembly Machine

Main Features

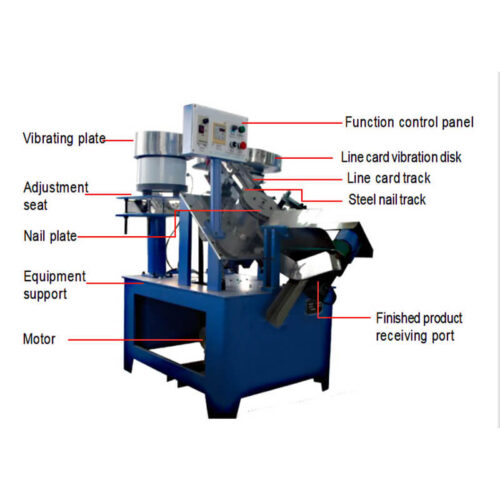

The principle of the Scalp Vein Set Assembly Machine: First, manually feed the material to the vibrating plate automatically, start the machine, the machine puts the tube on the machine to arrange and flatten, and then apply glue to the short tube and heparin tube on one end of the tube, and install the stop clamp on the other end. After the glue is finished, install the needle holder and the screw cap, and finally automatically unload the assembled product.

Technical Parameters

| Scalp Vein Set Assembly Machine | |

| Power Supply | 380V |

| Power | 5.5Kw |

| Air Source | 4-8Kg |

| Output | 50Pcs/Min |

| Operator | 1Person |

| Qualified Rate | 99% |

Vein Set Assembly Machine Main Functions

- Cutting and stripping: The machine cuts the tubing to the required length and strips the ends to allow for the attachment of connectors.

- Connector assembly: The machine attaches connectors to the tubing to allow for easy attachment to medical devices.

- Tubing insertion: The machine inserts a needle or other device into the tubing, which will be used to access the patient’s vein.

- Sterilization: The machine sterilizes the tubing and components to ensure they are free from harmful bacteria or pathogens.

- Quality control: The machine performs quality control checks to ensure that each vein set meets the required specifications and is free from defects.

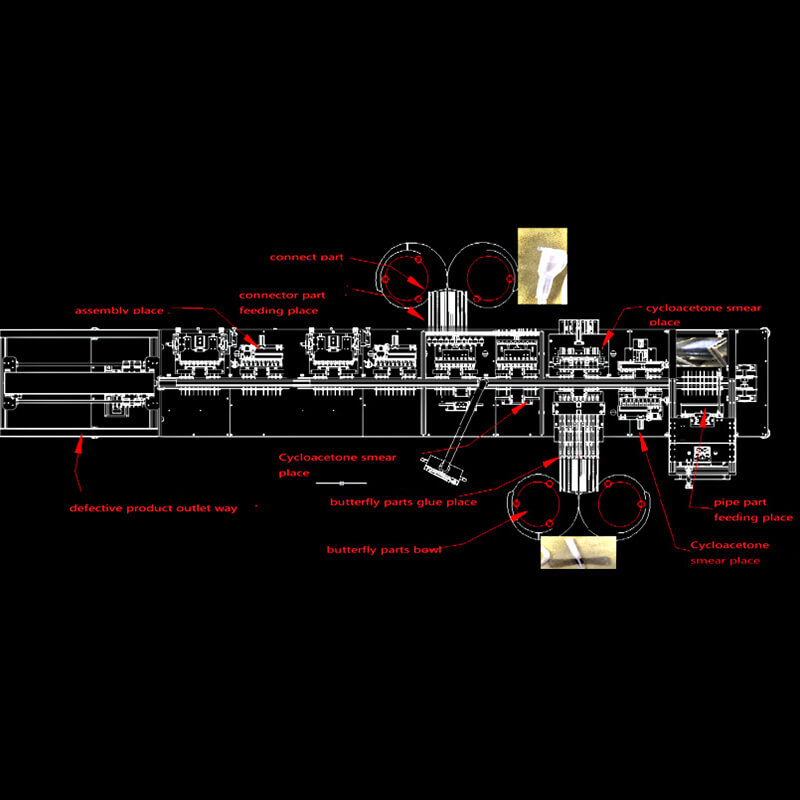

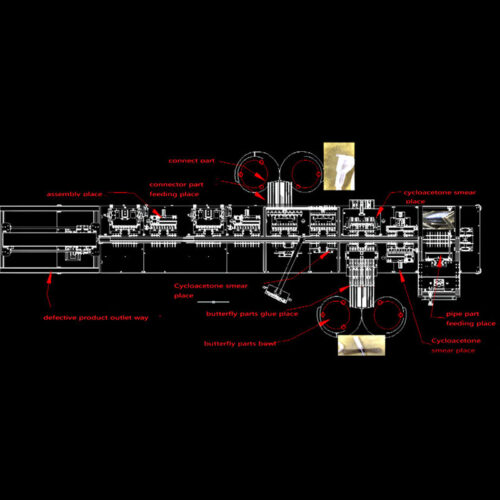

Scalp Vein Set Assembly Machine Production Line

- Machining and preparation of parts and assemblies.

- Automatic or manual assembly and installation.

- Testing and inspection on the production line.

- Packaging and shipping of finished products.

- The specific design and configuration of a production line depending on production requirements, available technology and equipment, and quality standards.

Reviews

There are no reviews yet.