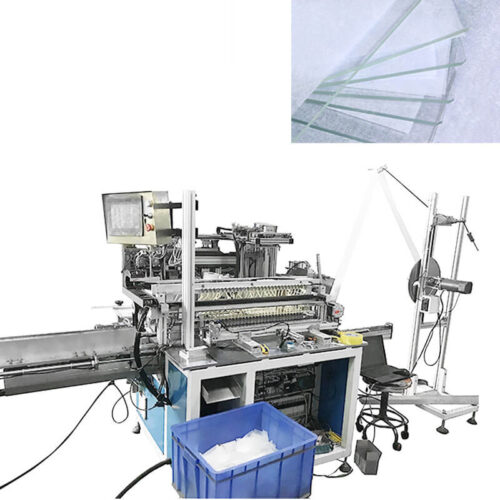

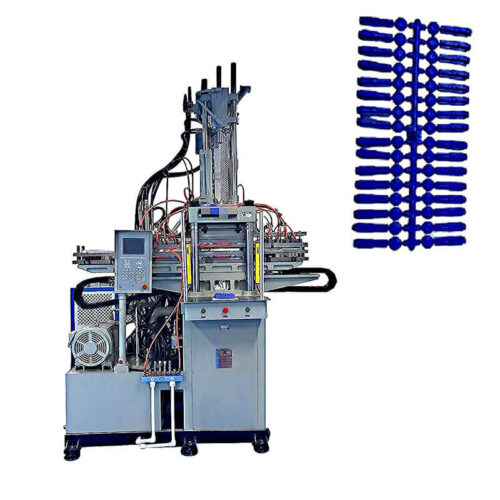

Battery Clip Assembly Machine

Main Features

The Battery Clip Assembly Machine is not very different from other plastic clips, wood clips, and metal clip assembly machines. The main reason is that there is a difference between cutting the casing and installing the casing. The machine uses a vibrating plate to transport the clips and metal parts to the central processing platform for assembly. It adopts advanced PLC and displays for operation, which is efficient, safe, and simple.

Technical Parameters

| Machine Name | Battery Clip Assembly Machine |

| Model | High Speed |

| Air | 1.2Mpa |

| Weight | 540Kg |

| Power | 220V |

| Measurement | 3.9Cbm |

| Speed | 30Pcs/Min |

| Guarantee | 1Year |

Battery Clip Assembly Machine Main Functions

- Automatic feeding: The machine can feed the battery clip parts into the machine for assembly through the automatic feeding system to improve production efficiency.

- Automatic assembly: The machine can automatically complete the assembly process of the battery clip, including operations such as alignment, assembly, and compression of parts.

- Detection function: The machine can detect whether the assembled battery clip meets the quality requirements, such as whether the clamping force is appropriate, whether the connection is firm, etc.

- Fault diagnosis: The machine can automatically detect faults during the operation of the machine, and prompt the operator to deal with them through the alarm system.

- Data recording: The machine can record the production data of each batch, such as production quantity, quality indicators, etc., which is convenient for management and quality traceability.

Battery Clip Assembly Machine Production Line

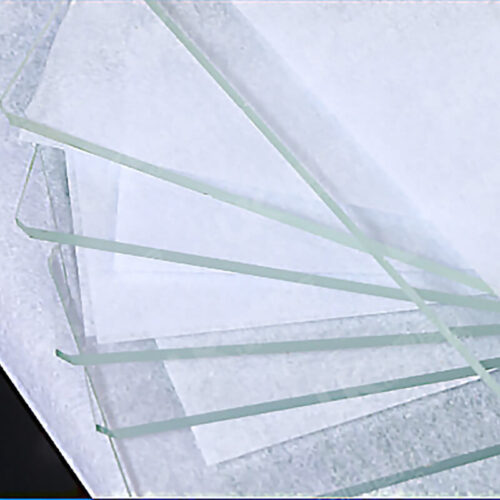

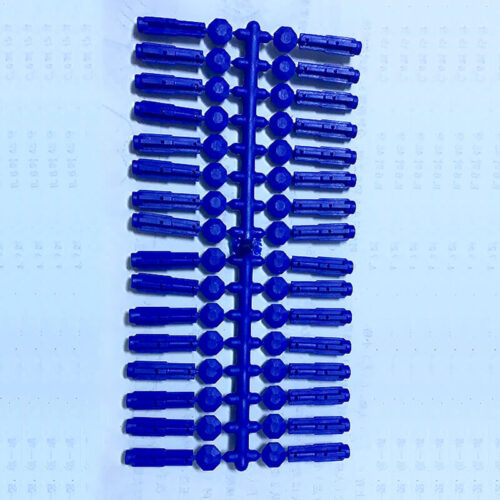

- Rack placement: place the clips and other components in a suitable position for use in subsequent processes.

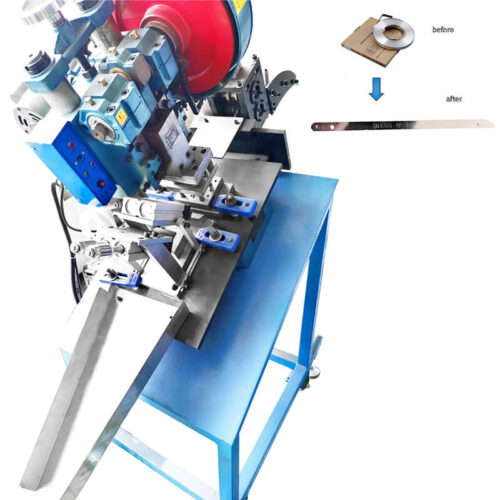

- Component processing: Cutting, drilling, etc. of clips and other components to meet the requirements of subsequent processes.

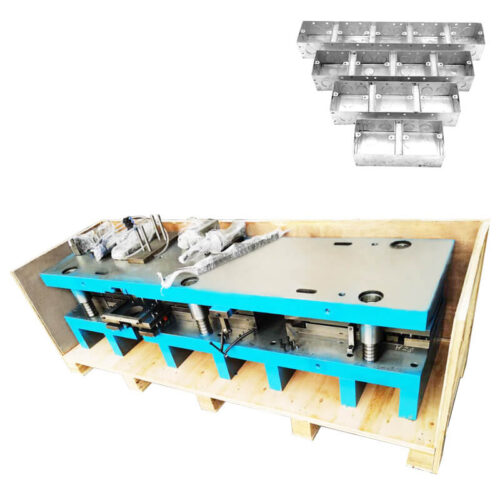

- Clip installation: Place the clip on the battery post and apply pressure to ensure good contact between the clip and the post.

- Welding: Weld the clip to the pole to ensure clamping strength and current continuity.

- Quality inspection: Carry out a visual inspection, clamping strength test, and resistance test on the welded battery clip to ensure its quality meets the standard.

Reviews

There are no reviews yet.