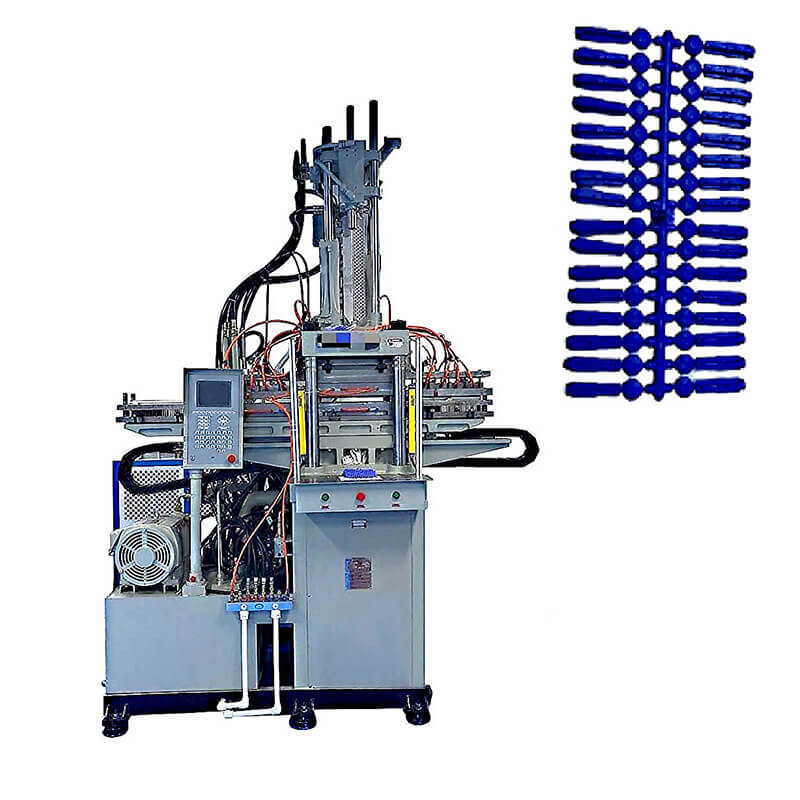

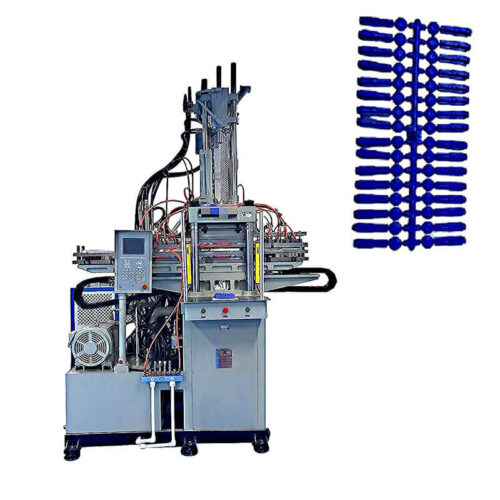

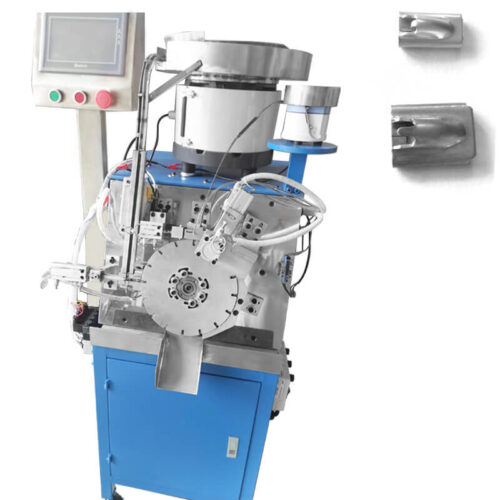

Blood Lancet Mold Machine

Main Features

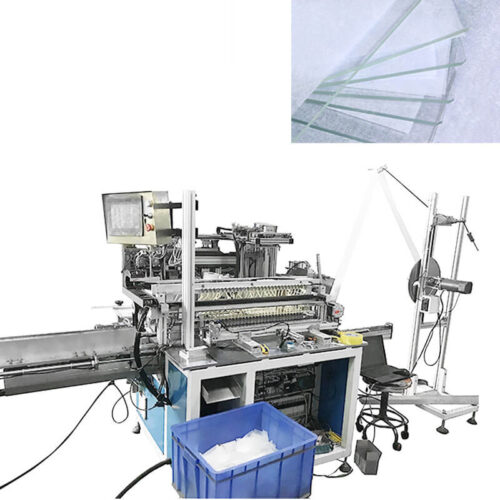

Blood Lancet Mold Machine is widely used in the medical industry. In the past, the injection of lancets required manual needle placement. This process was slow, with high-risk factors, and low productivity. This production line adopts the third-generation needle placement system and uses a robotic arm to take products. One robotic arm can take products from two injection molding machines at the same time, which is safe and fast. At the same time, we provide machines with customized molds and cutout handles. At the same time, a CDD camera can be installed to detect the quality of the inner needle of the product and reject defective products. This production line reduces the number of labor to a minimum, while also ensuring the safety of employees and the qualified rate of products to the greatest extent.

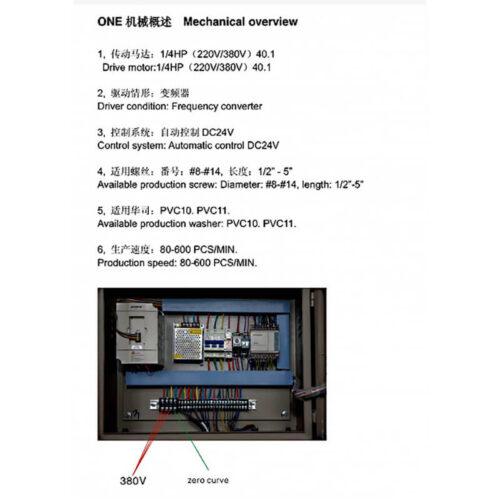

Technical Parameters

| Speed | 200,000Pcs Per 8Hours |

| Measurement | 1.2×0.6×2.5M |

| Delivery Time | 10Days |

| Guarantee | 1Year |

| Power | 220V |

| Certificate | Ce |

| Package | Bulk |

| Hs Code | 8479899990 |

| Machine Name | Blood Lancets Mold |

| Machine Weight | 1.3Ton |

Blood Lancet Mold Machine Main Functions

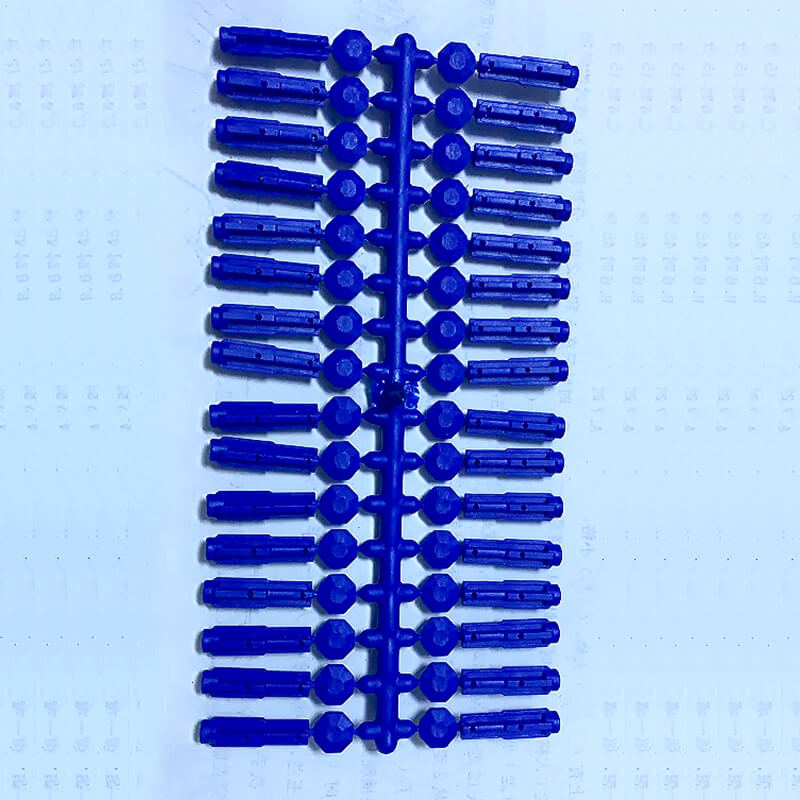

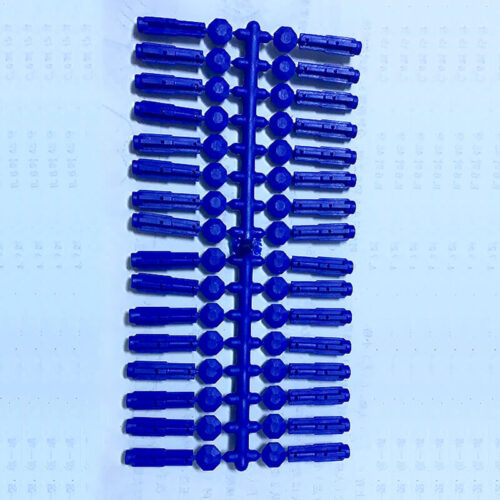

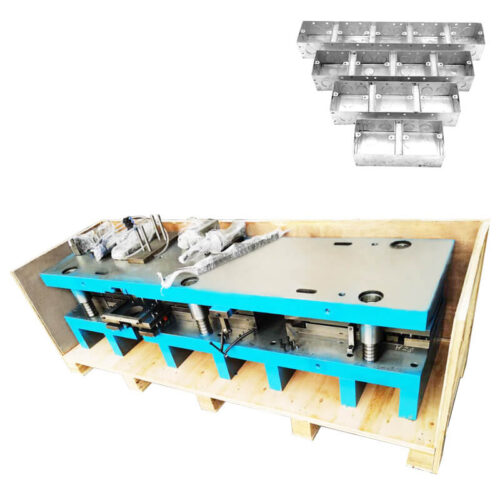

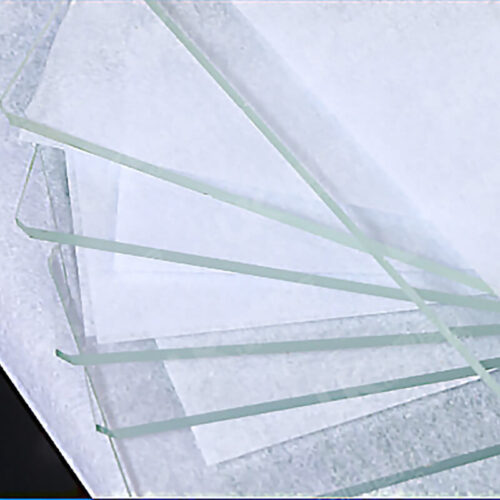

- Mold manufacturing: The blood collection needle mold machine can manufacture blood collection needle molds of different specifications and shapes according to user needs, including the blood collection needle head, pipe and blood collection needle cover, and other parts.

- Automated production: The blood collection needle mold machine can automatically complete the manufacturing process of the blood collection needle mold, thereby improving production efficiency and reducing labor costs.

- Accuracy control: The blood collection needle mold machine has high-precision processing and measuring equipment, which can ensure the accuracy and quality of the size, shape, and surface finish of the blood collection needle mold.

- Multi-functional operation: the blood collection needle mold machine can realize the manufacture of different types and specifications of blood collection needle molds by changing the processing program and process parameters, so as to meet the needs of different users.

Blood Lancet Mold Machine Introduction

The Blood Lancet Mold Machine is a kind of equipment specially used to produce blood collection needle molds. A blood collection needle is a kind of medical device, which is often used in clinical blood collection and is the basis of blood examination and diagnosis.

A blood collection needle mold machine is usually composed of an injection machine, a mold, an automated robotic arm, and a control system.

Reviews

There are no reviews yet.