Cable Tie Manufacturing Machine Features

- When it comes to state-of-the-art cable tie production machines, our pioneering three-master design stands out.

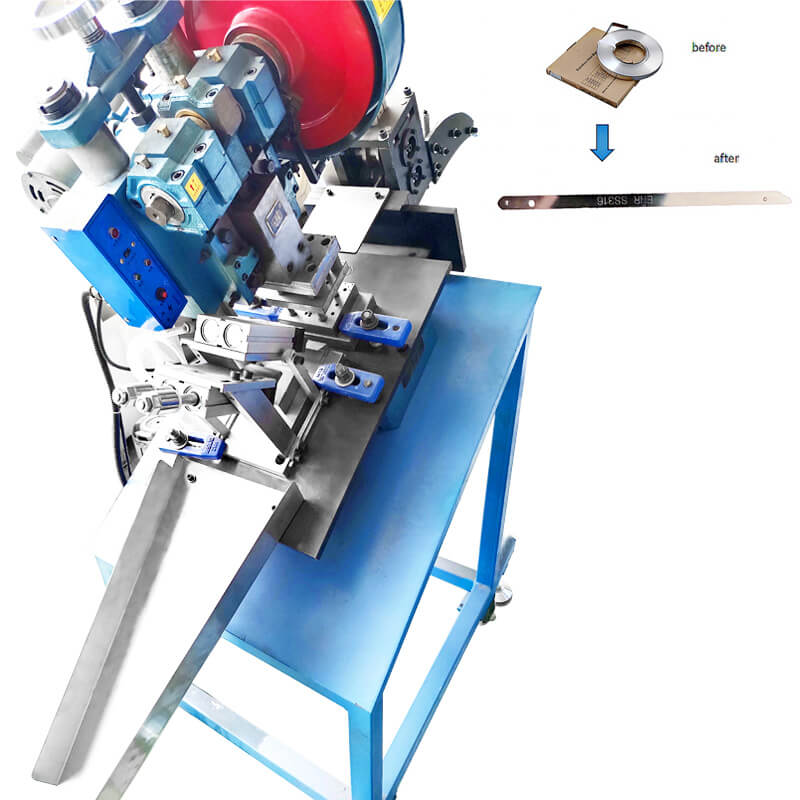

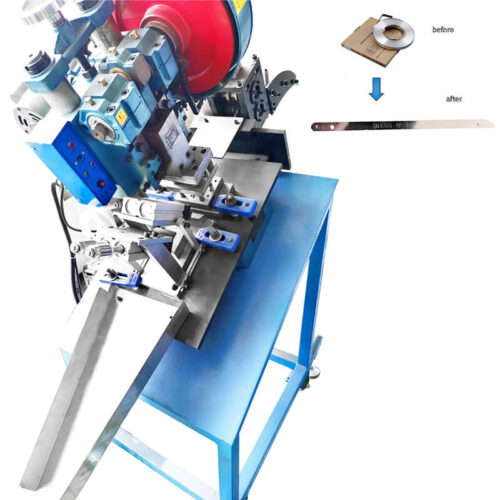

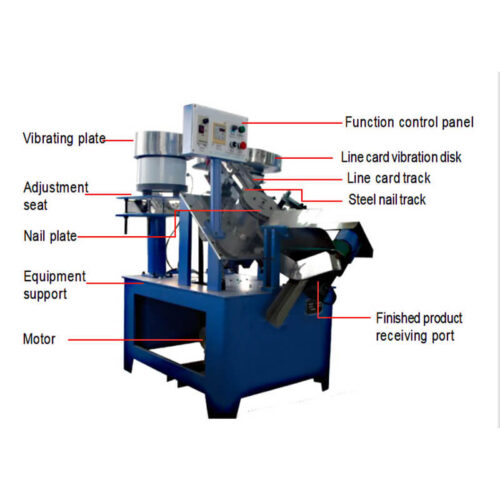

- The first in this innovative trio is the cable tie manufacturing machine.

- It is equipped with a flat electronic tracking feeder, which helps ensure precision and improve overall efficiency in the production process.

- Following that, the second is a versatile flattening machine.

- Its adjustable settings offer a range of sizes from 4.6, 7.9, to 11.2, enabling customization to meet individual client requirements.

- This adaptability elevates the functionality of the cable tie making machine, providing a superior production experience.

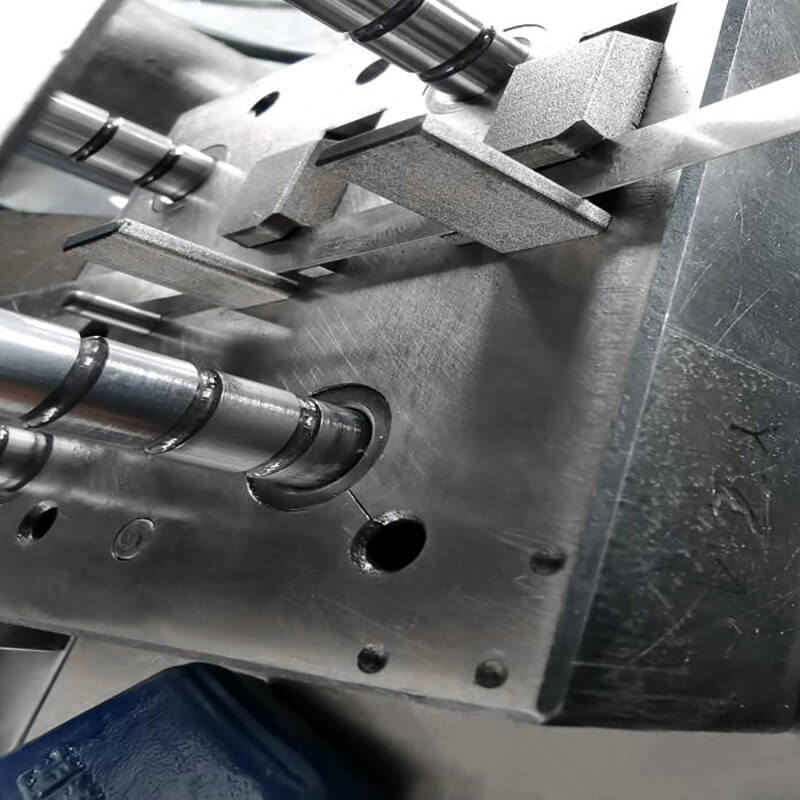

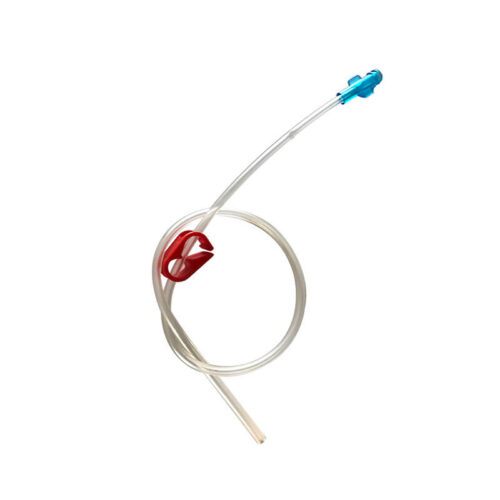

- The third, a cutting machine, comprises a comprehensive assembly of a punching machine, a bending die, and a wire drawing machine.

- Notably, the bending die is a unique feature that can be tailored to the customer’s specifications, adding an extra layer of personalization to the process.

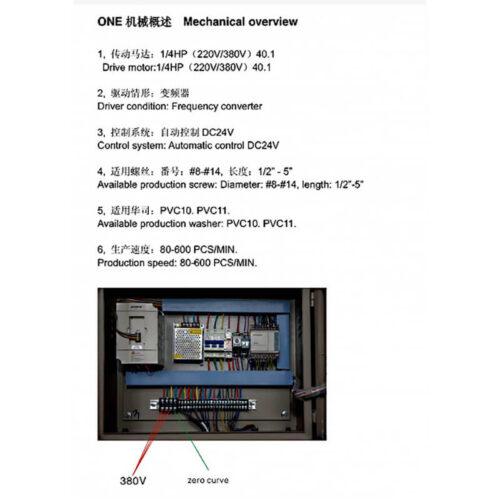

- The entire operation of this cable tie production machine is managed via a switch or a PLC screen.

- This user-friendly interface ensures the machine is easy to operate and fast, paving the way for a seamless, efficient cable tie manufacturing process.

Featured Video

Conclusion

With durable materials and a robust design that ensures years of trouble-free operation, our cable tie production machine is constructed to endure and maintain consistent performance.

Plus, our competitive cable tie making machine price makes it an affordable investment for your business.

Whether you’re just starting out or looking to upgrade your current equipment, our cable tie production machine is the perfect choice.

FAQ About Cable Tie Manufacturing Machine

Yes, we also provide other equipment and accessories related to cable tie production to meet customers’ needs.

Reviews

There are no reviews yet.