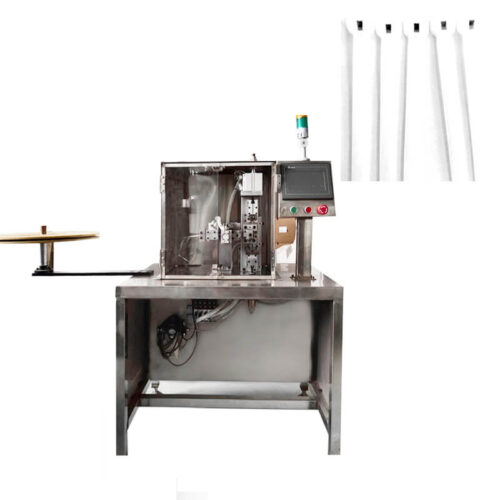

Dental File Handle CNC Machine

Main Features

The syringe needles polishing and testing machine incorporates branded high-definition CCD and lens, coupled with an industrial-grade host and reliable hardware, ensuring optimal performance. It boasts adjustable parameters for all types of needle tubes, seamlessly adapting to the detection of various specifications. The detected parameter data is immediately displayed on the intuitive interface, providing real-time insights. Operators can effortlessly teach the machine the desired length and width of needle tubes directly on the program interface, ensuring precision tailored to specific needs. The syringe needles polishing and testing machine features breakpoint memory and power-off automatic protection functions, safeguarding against unexpected interruptions and ensuring continuity in the production process. Furthermore, the system automatically classifies needle tubes identified as NG (not good) or unqualified with distinct labels, prominently displaying them on the upper interface for immediate operator observation. This not only streamlines quality control but also enhances operational efficiency. Additionally, the syringe needles polishing and testing machine saves images of defective needle tubes, including those labeled as NG or unqualified, directly to the computer, allowing for easy retrieval and review at any time.

Reviews

There are no reviews yet.