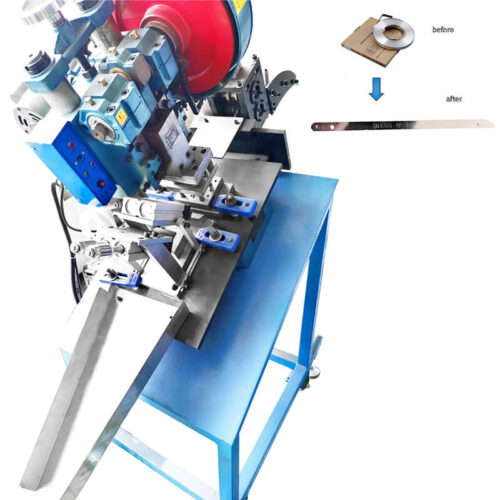

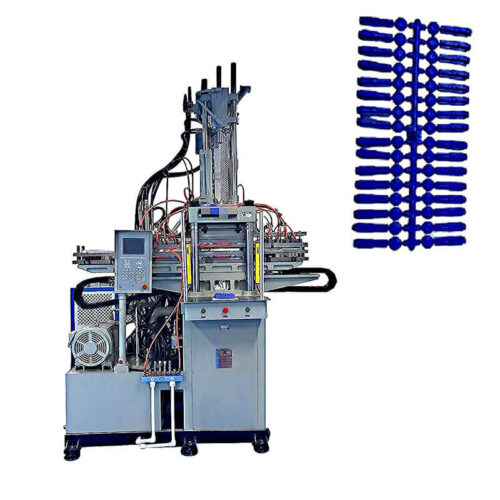

Dowel Nail Assembly Machine Features

- The vibrating plate adopts solenoid valve and blowing device to increase the feeding speed and stability of the long screw.

- The vibrating plate is fixed with supporting feet, and the nylon feeding can be smoother, avoiding the unstable feeding caused by resonance.

- Use a Mitsubishi PLC to avoid damage to the PLC due to vibration.

- Airtac is used for the cylinder.

Featured Video

Conclusion

We have worked on several projects and if you wish you can send us your ideas.

So our team can be ready to discuss functional specifications.

We will customize the most suitable plan for you according to your needs.

If you would like to inquire about information, please get in touch with us by email.

About Dowel Nail Assembly Machine

Regular Cleaning: Keep equipment clean by removing residue and debris from inside the assembly machine.

Lubrication and Maintenance: Lubricate and maintain lubricated parts on a regular basis as recommended by the equipment manufacturer.

Regular inspection: Regularly check the transmission parts and electrical connections of the equipment to ensure its normal operation.

Timely maintenance: Repair or adjust the found faults or abnormalities in time to avoid affecting production.

This machine is suitable for various industries that need to use dowel nails, such as manufacturing, construction, furniture manufacturing, etc.

Dowel nails are widely used in the assembly process for fixing and connecting parts.

Increased production efficiency: Automating the assembly process can greatly increase the production efficiency of dowel nails.

Reduce labor cost: reduce the need for manual operation and reduce labor cost.

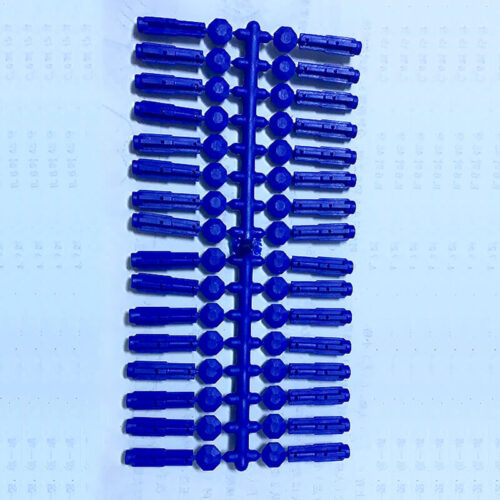

Precise and Consistent: A mechanized assembly process ensures precise fit and consistent quality of the dowel nails.

Reviews

There are no reviews yet.