Hose Clamp Manufacturing Machine Features

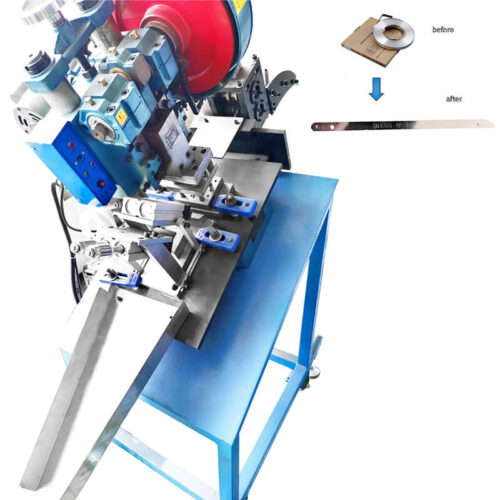

- Our hose clamp assembly machine is designed to streamline the manufacturing process with its efficient functionality.

- The machine facilitates the seamless transportation of rolled steel belts to its cutting mechanism.

- Simultaneously, a vibrating plate transports the hoop head to the designated position for welding.

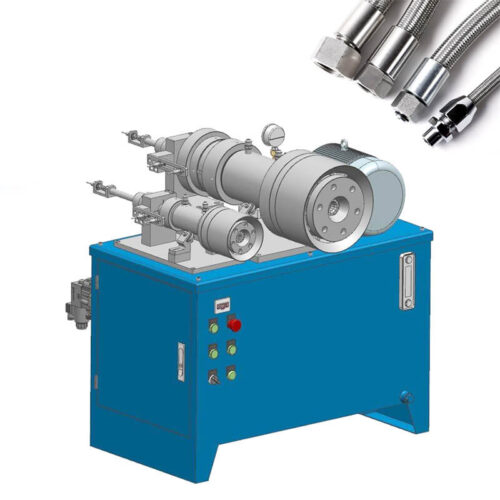

- To ensure optimal working conditions, our hydraulic hose clamp machine is equipped with a dust-proof shell.

- This not only reduces noise and dust levels but also prioritizes operator safety.

- Incorporating Mitsubishi PLC and a display screen, our hose clamp machine boasts a sleek and elegant design.

- The inclusion of an alarm device ensures prompt notification in case of material jamming, allowing for quick resolution and minimal downtime.

- This significant reduction in the required workforce translates to substantial time savings for employees.

Featured Video

Conclusion

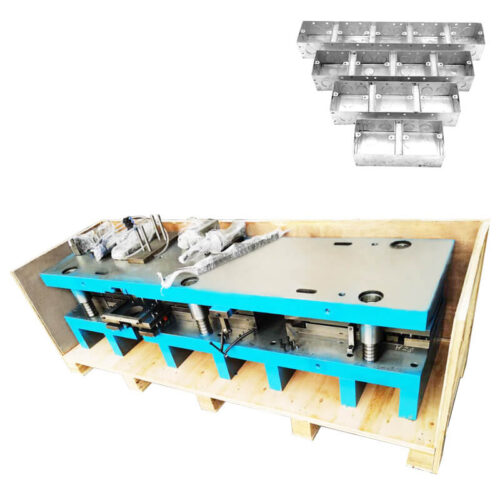

Precision-engineered and constructed using premium-grade materials, our hose clamp making machine is designed to meet the highest standards of quality.

Equipped with advanced features, it enables seamless assembly and ensures precise production of hose clamps.

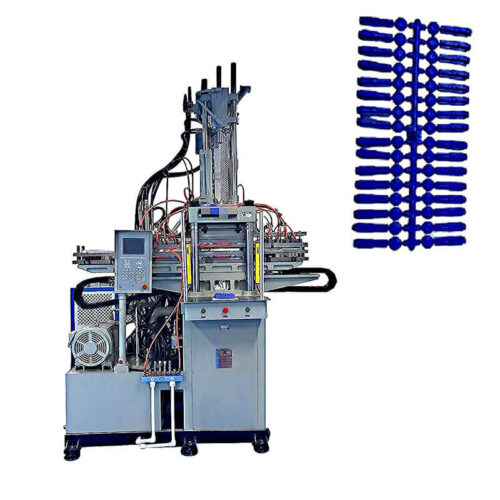

The user-friendly interface simplifies operation, allowing for easy adjustment of settings and effortless machine maintenance.

At our manufacturing facility, we prioritize quality control at every stage of production.

Whether you require a hose clamp making machine or a hose clamp assembly machine, we have the solution for your business.

FAQ About Hose Clamp Assembly Machine

Yes, our hose clamp manufacturing machine is designed to handle various materials, including stainless steel, galvanized steel, and other metals commonly used for hose clamps.

With its welding capabilities, the machine can seamlessly join components, creating strong and reliable connections.

This results in improved productivity, higher-quality output, and ultimately, greater customer satisfaction.

Reviews

There are no reviews yet.