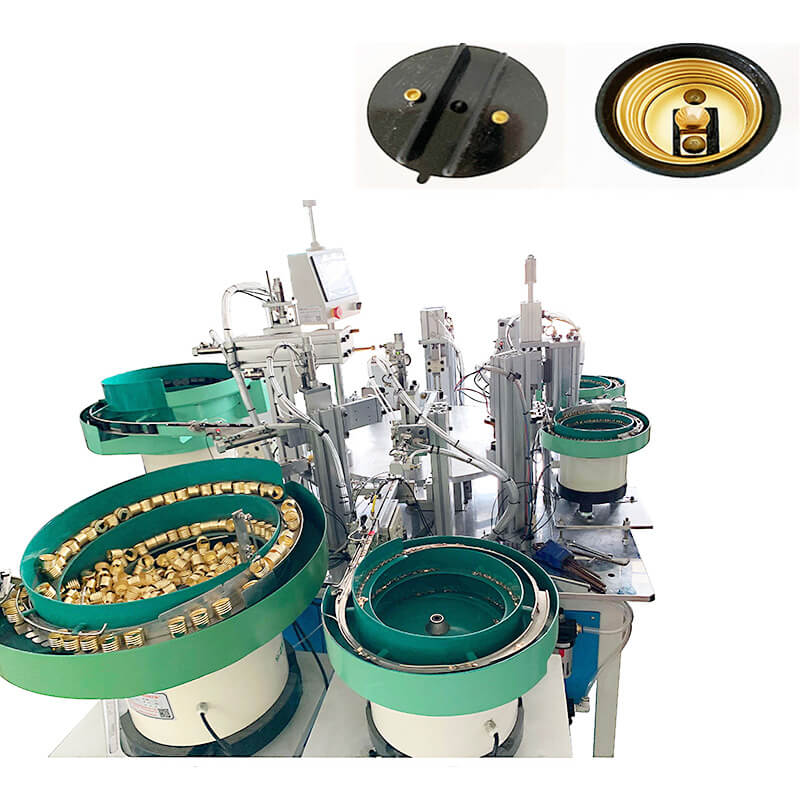

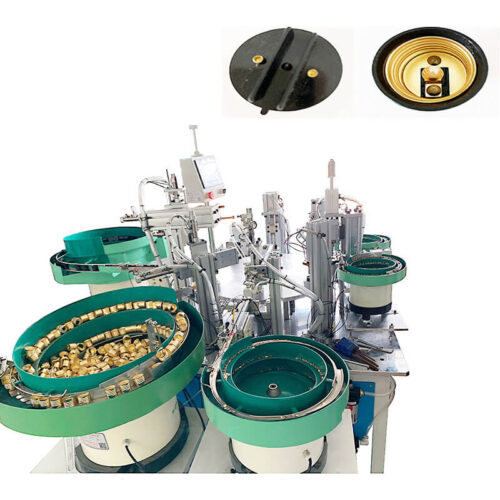

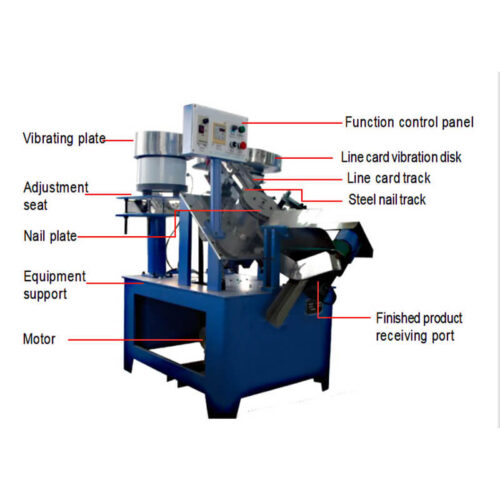

Lamp Holder Socket Assembly Machine Features

- This lamp holder socket assembly machine is a base assembly machine, and a lamp base is a complete machine with 4 parts.

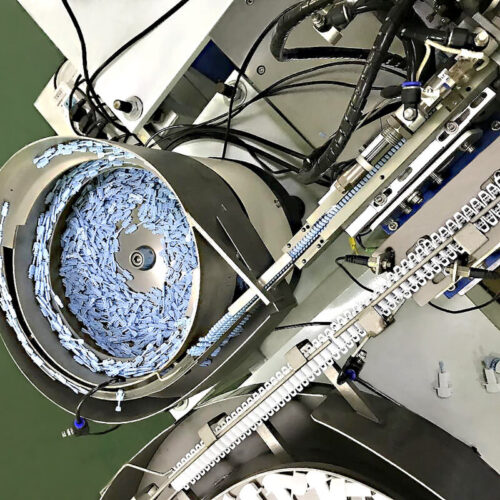

- First, the plastic shell, the metal inner shell position, and the 2 copper sheet lamps are transported to the designated place by 4 vibrating discs, and the whole is carried out.

- At the same time, the 2 copper sheets are pressed on, and the product is successfully completed.

- It is simple and efficient, saves labor, and can avoid the uneven strength of manual riveting of copper sheets.

Featured Video

Conclusion

We have worked on several projects and if you wish you can send us your ideas.

So our team can be ready to discuss functional specifications.

We will customize the most suitable plan for you according to your needs.

If you would like to inquire about information, please get in touch with us by email.

About Lamp Holder Socket Assembly Machine

Using the machine requires the operator to be familiar with the operation method and safety precautions of the machine.

They need to receive relevant training to understand the machine’s function, programming, and troubleshooting knowledge.

The maintenance of the assembly machine includes regular cleaning, lubrication, and checking whether the various parts of the machine are operating normally.

In addition, pay attention to complying with the maintenance requirements in the machine instruction manual to ensure the stable operation and life of the machine.

The machine can greatly improve production efficiency, reduce manual operations, and ensure the consistency and accuracy of assembly.

It also reduces the risk of human error and quality issues, increasing product consistency and reliability.

Reviews

There are no reviews yet.