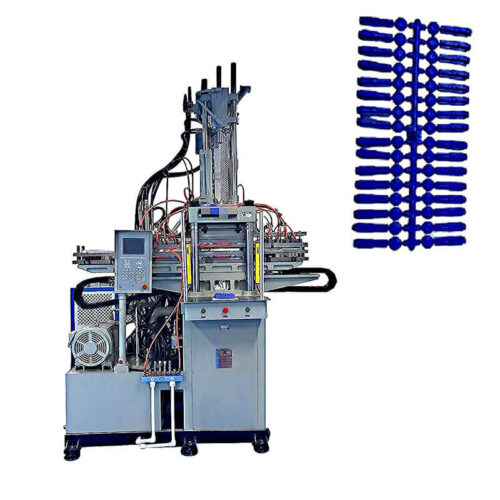

Syringe Needles Trimming Machine

Main Features

High efficiency: It can quickly complete the burr removal work on pipe fittings, greatly saving time and labor costs.Automated operation: No need for excessive human intervention, automatically complete the entire process of pipe entry, pipe brushing, and pipe exit.Precise control: Through advanced control systems, precise control of speed and other parameters to ensure high quality and consistency of pipe fittings.Multi-functional adaptation: It can handle pipe fittings of different diameters and materials, and has strong versatility.Stable and reliable: The use of high-quality components and stable structural design ensures long-term stable operation and reduces the occurrence of failures.

Technical Parameters

Syringe Needles Trimming Machine

Main Functions

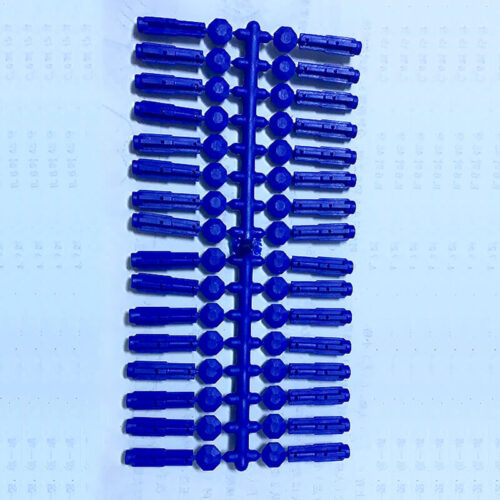

A syringe needles trimming machine is a specialized piece of equipment designed to optimize the production process of syringe needles. Here’s a more detailed explanation of the benefits you mentioned:

1. **Improve Production Efficiency and Quality**:

– By automating the trimming process, the machine significantly reduces the time taken to produce each needle. This leads to increased output and productivity.

– Automated trimming ensures precision and consistency in the final product, reducing defects and waste. It also eliminates human error, which can be a major source of quality issues in manual processes.

2. **Improve the Working Environment and Reduce Labor Intensity**:

– Manually trimming syringe needles can be a repetitive, labor-intensive, and potentially hazardous task. Automating this process removes employees from this physically demanding work, improving their overall job satisfaction and reducing the risk of work-related injuries.

– The machine operates in a controlled environment, minimizing exposure to dust, debris, and sharp objects. This not only improves workplace safety but also helps maintain a cleaner, more hygienic work environment.

3. **Ensure the Consistency of Pipe Cleanliness and Lay a Good Foundation for Subsequent Processes**:

– Trimming is an essential step in preparing syringe needles for further processing, such as packaging and sterilization. An automated trimming machine ensures that each needle is cleaned and trimmed to the same precise specifications, setting the stage for high-quality downstream processes.

– Cleanliness and precision are critical in the medical device industry, where even the smallest imperfection can compromise patient safety. Automated trimming helps maintain these standards.

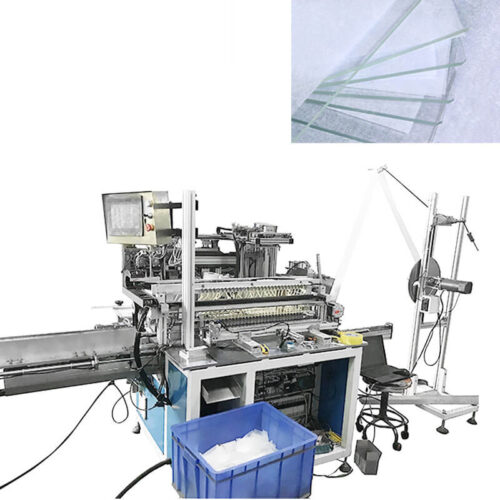

4. **Promote the Development of Related Industries and Become an Indispensable Equipment in Modern Production**:

– The introduction of automatic tube brushing machines (and similar automated equipment for syringe needles) has transformed the manufacturing landscape. By streamlining production processes, reducing costs, and improving quality, these machines have fueled the growth of the medical device industry.

– As the demand for medical devices continues to rise, the need for efficient, reliable production equipment becomes even more pressing. Automated trimming machines are now considered an essential part of modern manufacturing processes, enabling companies to compete effectively in an increasingly competitive global market.

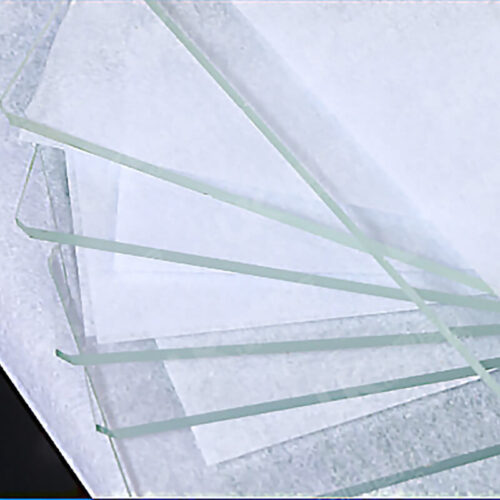

Syringe Needles Making Machine

Reviews

There are no reviews yet.