Umbrella Squid Hook Making Machine Features

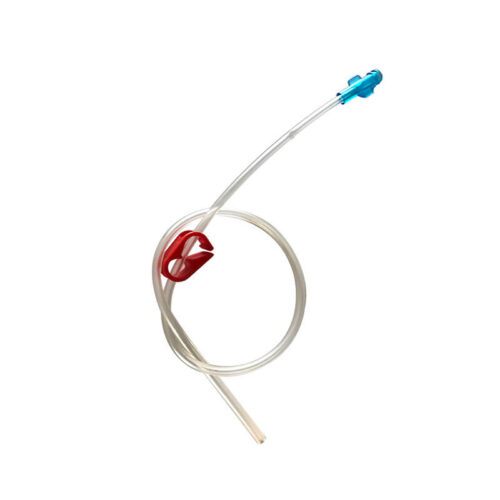

the machine will put the needles into the ring It is semi-auto, which means it needs one worker to open the machine all the time.

Featured Video

Conclusion

The production process for the Umbrella Squid Hook necessitates a comprehensive suite of machinery, each crucial to its successful fabrication.Firstly, it requires a wire cutting machine, indispensable for precisely cutting the raw wire material to the desired lengths.Moving on, a tip polishing machine is essential to refine the ends of the cut wires, ensuring a smooth and finished appearance.Subsequently, the combing and forming machine takes over, intricately the wires into the Umbrella Squid Hook. This step is vital in creating the unique structure and functionality of the product.Following this, an inserting machine is needed to accurately position and fasten any necessary components or accessories into place. This automation ensures efficiency and precision in the assembly process.Lastly, a dedicated assembly machine completes the production line, integrating all the individual parts into the final Umbrella Squid Hook product. This comprehensive machinery ensures that every step of the manufacturing process is streamlined and optimized, resulting in a high-quality finished product.In conclusion, we possess the entire line of equipment necessary for the production of the Umbrella Squid Hook, from wire cutting to final assembly, demonstrating our comprehensive capabilities in this field.

About Suture Needle Bending Machine

The automated machine seamlessly integrates the needles into the ring, ensuring a tight and secure hold between the two components. This process is categorized as semi-automatic, necessitating the continuous presence of an operator to initiate and maintain the machine’s operation. The efficiency of this semi-automated system surpasses manual methods, offering a significant boost in speed and productivity. With the machine handling the intricate insertion of needles, the workload for the operator is minimized, allowing for a more streamlined and expedited production process.

Reviews

There are no reviews yet.