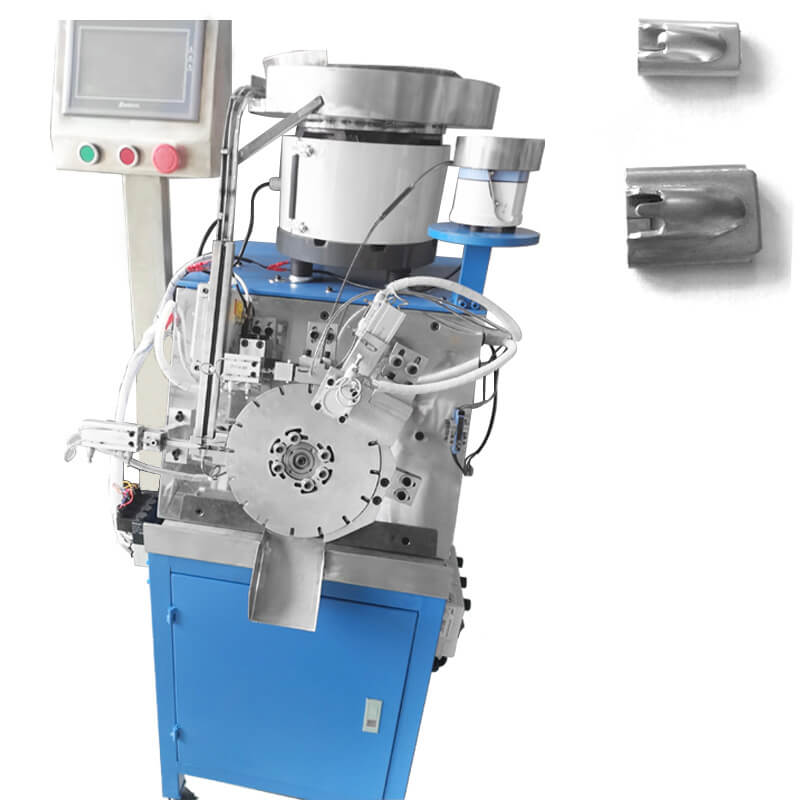

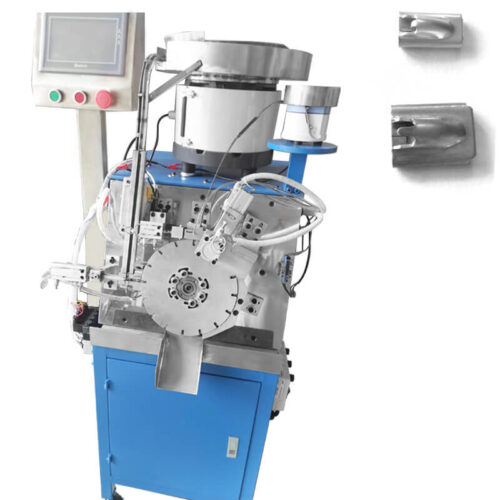

Cable Tie Production Machine Features

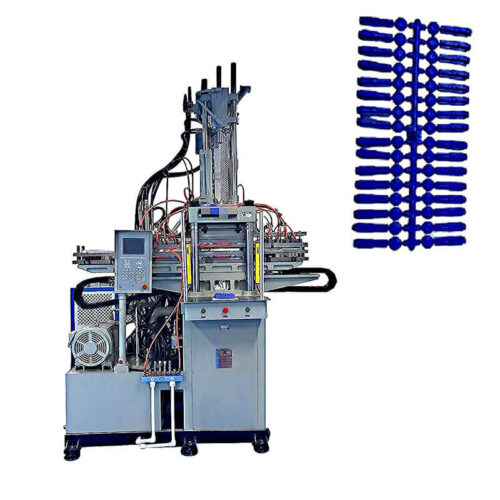

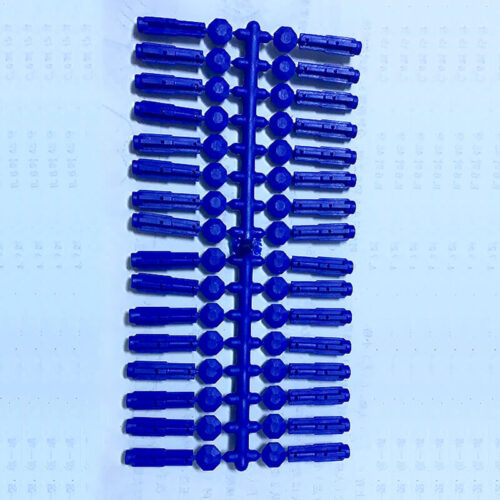

- Our cable tie manufacturing machine is specifically designed to meet the demands of manufacturing high-quality cable tie hoops with precision and ease.

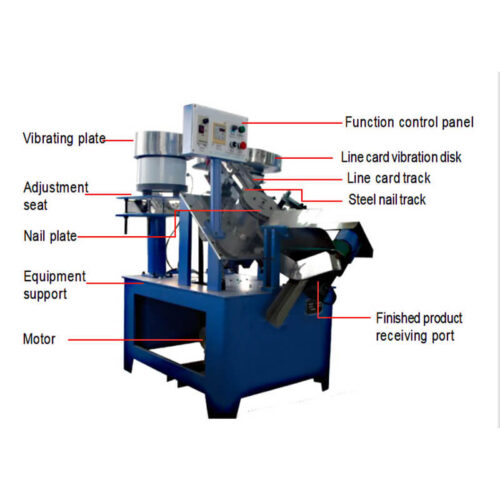

- To streamline the production process, our cable tie making machine utilizes a vibrating disk mechanism.

- This mechanism efficiently transports the steel balls to the designated location, ensuring a continuous supply of materials for the manufacturing process.

- Additionally, the vibrating disk is responsible for transporting the hoop to the central processing unit, where the assembly takes place.

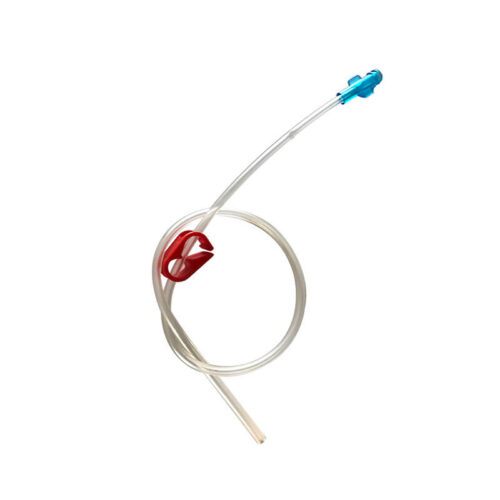

- The cable tie manufacturing machine incorporates an air cylinder that plays a crucial role in the assembly process.

- The air cylinder is responsible for pushing the beads into the hoop, ensuring a secure and reliable connection.

- Once the cable tie hoop is assembled, the finished product freely falls into a box located on the ground.

- This allows for easy collection and subsequent packaging of the cable tie hoops, enhancing the overall efficiency of the manufacturing process.

Featured Video

Conclusion

Investing in our cable tie manufacturing machine means investing in a reliable solution that combines precision, efficiency, and affordability.

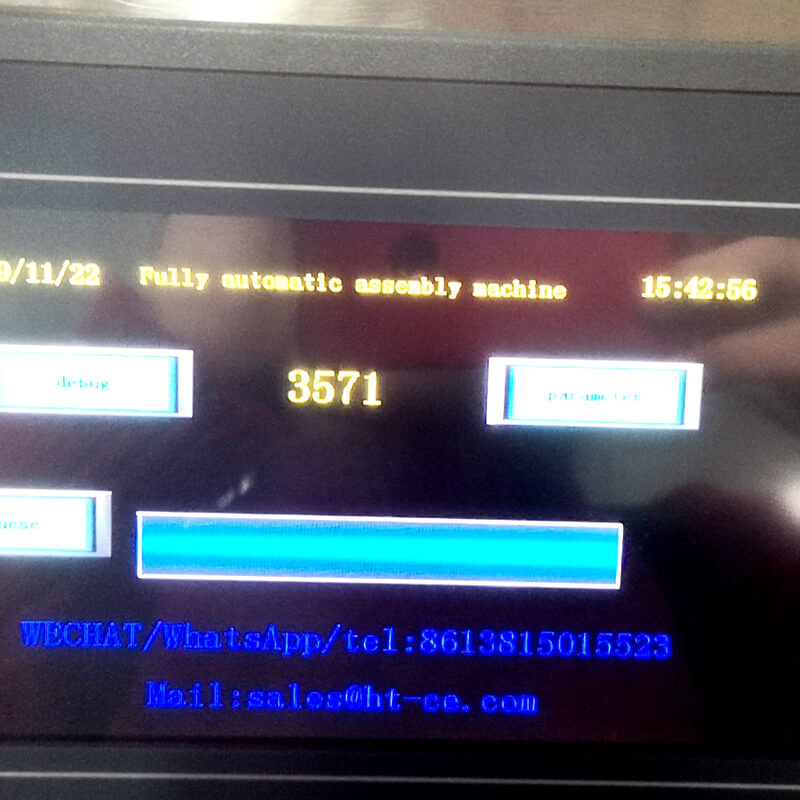

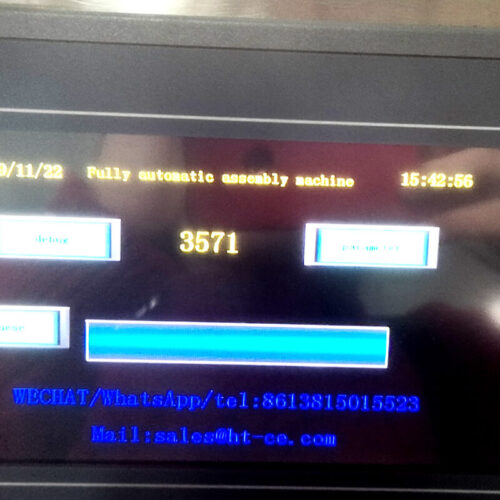

It has specific parameters, including an air pressure range of 0.5-0.7Mpa and customizable speed, our machine is designed to enhance your cable tie manufacturing process and help you achieve your production goals.

With its advanced mechanisms and automated features, it significantly reduces production time and ensures high-quality output.

With its precise mechanisms and streamlined processes, our machine is the ideal choice for manufacturers in the cable tie industry.

We are dedicated to providing you with a high-quality machine at a competitive price, tailored to your specific requirements.

Reviews

There are no reviews yet.