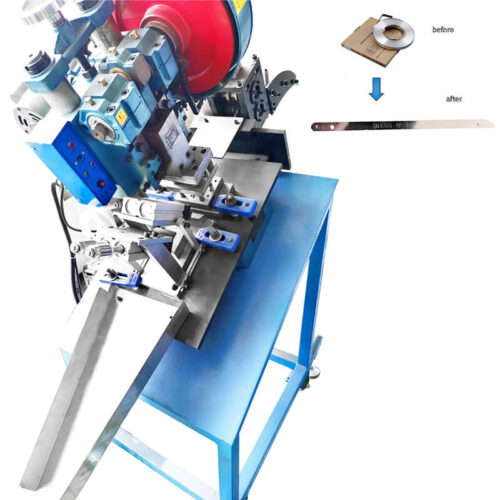

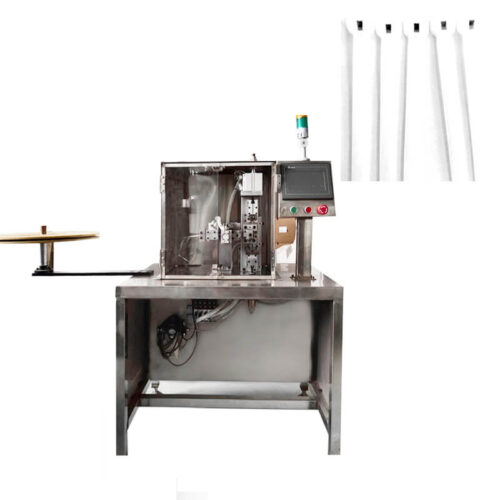

Suture Needles Drilling Machine Features

The intricate process of drilling commences with the meticulous orchestration of the drilling machine, which meticulously propels a precisely engineered needle out of the sturdy drilling die. This seamless transition is the culmination of advanced engineering and precise machinery, ensuring that every movement is executed with utmost accuracy.As the needle, now transformed into an active drill bit, emerges from its housing, it confronts the material to be pierced with steadfast determination. The drill bit, crafted from durable materials capable of withstanding immense pressure and friction, commences its rotary motion, spinning with a steady rhythm that belies its formidable power.The hole-making process ensues as the rotating drill bit gradually penetrates the surface of the material, its sharp edges carving out a precise circular path. The machine’s motor provides the necessary torque, driving the drill bit deeper and deeper, while simultaneously expelling the shavings and debris generated by the drilling action.The coordination between the machine’s motor, the rotating drill bit, and the steady feed rate ensures that the hole is drilled with uniformity and precision. The drill bit’s path is guided by the drilling die, which acts as a stabilizer, preventing any deviation from the intended trajectory. This meticulous control over the drilling process results in a hole that is not only accurately sized but also possesses impeccable straightness and smoothness.As the drilling action nears completion, the machine gradually reduces the feed rate and eventually halts the rotation of the drill bit. The needle, now retracted back into the drilling die, signals the end of the drilling cycle. The resulting hole, a testament to the machine’s precision and efficiency, stands as a vital component in the larger manufacturing or construction process, ready to fulfill its intended purpose.

Featured Video

https://youtu.be/4j5ojEfmaUo

Conclusion

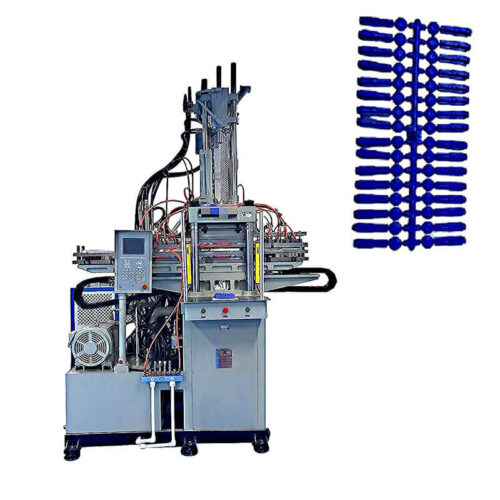

About Suture Needle Bending Machine

The fundamental operation of this machinery involves the pneumatic claw hand precisely dispatching the needle into the bending die, whereupon the pressing cylinder applies force to shape the arc, thereby executing the intended function.

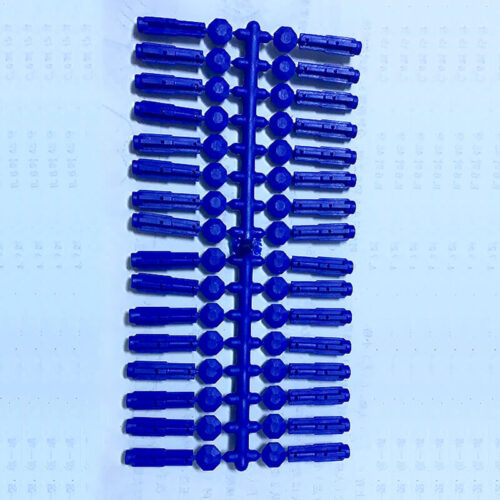

as it is a medical product, the material must be stainless steel.Right now the material is high quality and reasonable price, we use the ss420J2 made in Korea or 302/304 made in India which already has heating treatment.

Reviews

There are no reviews yet.